Flexible Automated Manufacturing

by Lifeboat Foundation Scientific Advisory Board member Michael Vassar.

Abstract

The integration of distributed information systems with modern manufacturing techniques promises to enable a massive change in both production and distribution. Techniques are described. Economic and regulatory implications are addressed.Paper

The contribution of industrial production to US employment is falling rapidly. This trend is likely to continue into the foreseeable future, ultimately bringing into existence a society where industrial production consumes as little labor as agriculture. The most obvious cause of this shift is globalization, but such an explanation is superficial.The primary cause of this shift is simply the improved capital associated with manufacturing and increased availability of manufactured goods. Domestic industrial production has increased substantially every year, yet productivity improvements outpace it, and production as a whole becomes a smaller part of the global economy. As a result, industrial production now employs less than 15% of the US workforce and accounts for less than 20% of the GDP. This can be compared with the 15% of the GDP associated with the health-care sector, but while the health care sector is growing by about 8% per year relative to the GDP, the manufacturing sector is shrinking by about 5%/year, so the two sectors should be expected to be approximately equally large in less than three years.

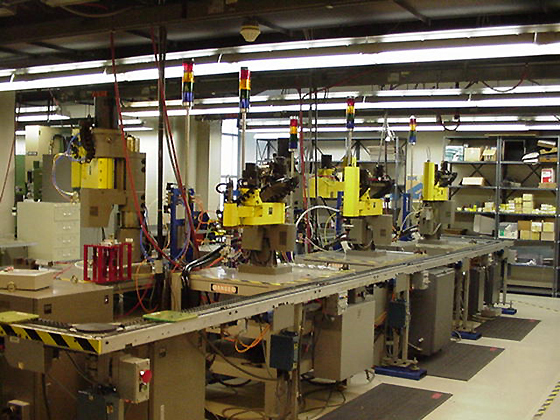

In addition to the radical improvements in productivity, US manufacturing capital is becoming far more precise and flexible, due to the use of industrial robotics and novel manufacturing techniques. Dragonfire, Drexel OYMBA’s award winning business plan, is an example of one of these novel manufacturing techniques. They hope to market inexpensive, rapidly manufactured, customized steel molds for injection molding, the process which has long enabled inexpensive manufacture of plastic parts and which can now shape other materials including ceramics and amorphous metals.

The trend towards flexible manufacturing was apparent in the form of reduced retooling costs as long ago as 1981, when Alvin Toffler invented the term “mass customization” to describe it. More recently the advent of widespread network access and powerful inexpensive CAD programs and VR bring the possibility of controlling manufacturing into the garage or even into the living room. While a networked society may continue to distribute discount goods via Wal-Mart and Fed Ex for some time, it is likely that luxury goods will increasingly be the product of mass customization.

In addition to traditional robotics and flexible manufacturing techniques, some novel manufacturing techniques promise to enable almost total flexibility of manufacture, so long as an appropriate supply of raw materials is available. This class of machine is being developed today in the form of 3-D printers and rapid prototyping devices. Surprisingly, the basic technological insight behind dot-matrix printing has been extended to roles varying from the production of spare parts on naval ships to the construction of housing. Small droplets of a chemical are sprayed into location and solidify in place.

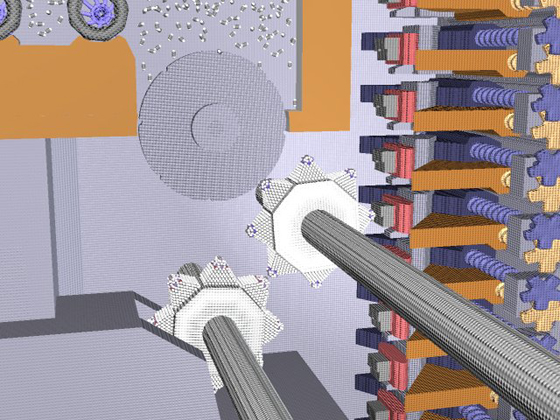

3D image created with a printer.

Soon, barring restrictions, nanotechnology devices such as lab-on-a-chip chemical synthesis and biological engineering systems will be mass produced. Such systems, in addition to their massive medical applications, will close the loop for 3-D printing by synthesizing a diverse array of chemical feedstocks from a small set of inexpensive chemicals. These feedstocks can be used by the printers to build more chemical chips. Eventually mechanochemical nanofactories should provide engineering capacity exceeding that of current economies into the living room.

Such ultra-flexible forms of capital are economically different from prior forms of capital in one important respect. Because they can be used to build almost anything, they can be used to build new flexible capital. For this reason, these forms of capital have a novel capacity for reproduction. Once a new type of flexible capital becomes inexpensive to use, due to the development of inexpensive sources of the relevant raw materials, that form of capital should become inexpensive to acquire, because it will be inexpensive to make, at least for those who already have some. All that is needed is an algorithm for its synthesis by some other flexible manufacturing system. Hardware becomes software.

It may be valuable to examine the necessary features of any disruptive manufacturing system.

The first requirement is that it function reliably without the need for any significant labor input. There are a number of ways in which this can be achieved, but fundamentally they revolve around the combination of high precision and reliability and redundant modular design.

If a manufacturing system is composed of discrete separable modules, and equipped with sensors capable of registering error, and if each module is redundant, then any single failure can be detected and can trigger an automated routine wherein the faulty module can be removed and replaced. Preferably, a replacement module can be constructed on-site by the manufacturing system using its normal inputs. If not, it is necessary that replacement modules be mass produced and available on short notice and at moderate expense.

The second requirement is that it be capable of constructing novel products in response to digital instructions without the need for retooling. This can be enabled by using digital programs to direct the flow of work-in-progress through any of a number of different modules. If the modules can be cheaply constructed, it is not necessary that each module be fully utilized. Some can be available for special applications even if they are only rarely used. Inexpensive modules also reduce the otherwise gratuitous expense of replacing an entire module whenever an error occurs. This option is necessary if the skilled labor requirement is to be minimized.

The third requirement is that a system be capable of working with a modest number of inexpensive general purpose raw materials. The more sophisticated the techniques for manipulating these materials, the fewer the materials that will be needed.

For instance, hydrocarbons can be distilled into fuel, lubricant, etc, processed to yield alcohols, waxes, fats, and other organic chemicals, polymerized to produce fibers or hard plastics, dehydrogenated to produce hydrogen, graphite, and carbon fibers. Lab-on a chip chemical processing units can carry out the production processes required for any of these transitions. Carbon nanotubes have a huge range of further applications, and can serve as semiconductors, conductors, or insulators for electronics applications. Other moderate substitutions to hydrocarbons yield carbon filters, catalysts, etc.

The final requirement is that the manufacturing system be able to assemble a copy of itself from inexpensive raw materials and with only a minimum requirement for labor, assembly, or separately prefabricated parts. Once such a system exists, it can reproduce itself exponentially, rapidly scaling up production capacity to meet any possible demand.

If it takes a system less than one day to manufacture 1% of its own mass, such a system can in principle produce twelve copies of itself in a year and over 1011 copies of itself (far more than the population of the Earth) in a decade. This is what is meant when it is asserted that such a manufacturing technology can be disruptive. It can completely replace any prior manufacturing infrastructure if it can work with the appropriate materials and if digital instruction sets exist to guide its processes.

3-D printing may not qualify as a disruptive manufacturing technology because it will be difficult for it to meet two of these criteria. First, the range of materials that it can work with is seriously restricted by the requirement that all materials must be capable of being sprayed as droplets. Second, the process depends on very high precision but is incapable of manufacturing parts with that same precision. As a result the potential for exponential manufacturing with digital printers is limited. It still warrants discussion here because it

- Already exists and has found a market, and

- Has the further benefit of enabling entirely new products which cannot be built using conventional manufacturing methods. Components of products can be manufactured in place, without the need for special compartments. The simplicity of the concept is also inspiring, given its widespread application and multiple variations. There is every reason to expect that more applications and extensions to this idea will be developed.

More importantly, this technique allows the process of a chemical reaction to occur under digital control, eliminating the need to devise a novel reaction pathway and acquire a novel set of reagents to enable every new reaction. A great variety of new molecules of great complexity can thus be synthesized. This class of syntheses bridges the gap between the precise but uncontrolled synthetic control currently held over chemical processes and the high tolerance but variable digital processes that are used today in macro-scale manufacturing. In essence, the top-down control of today’s robotics will be incrementally extended to ever smaller scales, and in being so extended will gain the advantages of older techniques for molecule level manipulation.

This manufacturing technique promises to fulfill all of the above requirements for a disruptive manufacturing technology, while providing the special flexibility of 3-D printing and more. Reliable, flexibly automated with digitally controlled retooling, capable of producing a wide variety of products from inexpensive raw materials, and capable of building a copy of itself from raw materials, early versions of such manufacturing devices have been investigated in detail in such publications as “Design of a Desktop Nanofactory” and “Nanosystems”.

Although the designs that have been analyzed so far are specialized in so far as they are only capable of catalyzing a small set of organic reactions, it has been demonstrated that this set is great enough to enable the construction of engines, motors, crude mechanical computers, and electronics. Over a decade of public scrutiny of Nanosystems by such individuals as Rice’s Nobel Laureate Richard Smalley and Harvard’s Professor Emeritus Robert Whitesides has failed to identify any technical errors.

Although mechanochemical manufacturing is extremely versatile, it does, like any technology, have certain limitations. First among these is that when one takes control of mechanical operations on the molecular scale it is necessary to perform a very large number of computations in order to construct anything of substantial size. Nanofactories can build both computers and copies of themselves, so a lack of computer hardware does not limit their functionality, but carrying out a great deal of computation will require a substantial energy source.

Nanofactory in action. Courtesy Lizard Fire Studios.

Current nanofactory designs require colossal energy inputs to power that computation. At current prices this energy would cost over $5/kg, making this process somewhat too expensive to provide a practical source of bulk materials. Of course, nanofactories can build facilities for energy production, reducing the cost of energy and thus of nanofactory products, but environmental costs associated with energy production imply that the cost of energy will remain non-negligible. If the demand for digitally nano-structured materials was great enough, energy might even become more expensive than it is today. Since variations of 3-D printing can be devised that utilize mud as their building material, there appears to be an economic niche for both approaches.

Another limitation of current nanofactory proposals is associated with their primary strength. Mechanical catalysis puts every atom precisely where it is desired, but in many cases we may simply not know where it is desirable to put a molecule. Many materials, especially those of a relatively unrefined biological origin, are already extremely complex at the molecular level, and many of the details of that complexity are unknown. Unless one knows how to describe such materials on an atomic level it will not be possible to assemble them with a molecular factory.

A partial solution to this problem may involve evolutionary programming. A programmer could describe the physical properties of a material and run a computer program that explores the properties of a variety of materials that your factory is capable of building. As part of the program, proposed materials could be modified slightly in a number of different ways. The modifications that resulted in a set of properties that more closely approximate the desired set could then be retained and modified yet again while the sets that did not match the designations as closely could be discarded. It is possible that rather than simulating materials it would be more computationally efficient to actually build these materials, evolving them against one another in a process analogous to the evolutionary process described above.

The obvious effect of all of this is a massive reduction in the cost of manufactured goods. This overstates one aspect of the impact of flexible manufacturing while ignoring other consequences. While industrial employment is likely to fall to near zero, the price of most manufactured goods is not dominated by the cost of labor. Other expenses, such as development, marketing, distribution, and inputs such as raw materials and energy account for a large fraction of the cost of most manufactured goods. More importantly, exponentially expanding manufacturing systems will still not lead to expanded production when firms have monopoly power and demand is inelastic.

Flexible manufacturing techniques, however, will eventually enable firms to more easily extend their production outside of current manufacturing specialties simply by acquiring the relevant software and building new capital in order to compete in another industry. This should greatly increase competition, driving firms out of existence and ultimately leading to a new equilibrium with a smaller number of more generalized manufacturing firms, at which point profits can again rise.

It is important to realize that cheap capital can reduce several of these non-labor expenses. Capital is used in the production of materials and of energy, and with adequate capital both can become available much more cheaply than they are today. Distribution also depends on large capital intensive networks, which can be built by automated systems.

Far more importantly, inexpensive automated manufacturing systems eliminate the need for much distribution by allowing products to be produced near their final destination. More or less extreme versions of this style of distribution are possible. Before there is a factory in every garage there will probably be one in every Wal-Mart, and possibly in the local gas station mini-market.

For any informed analysis of the economic consequences of exponentially expanding capital, it is important to understand that labor and capital can be substituted for one another across an extraordinary range of relative prices.

Labor can substitute for capital.

In Haiti, for instance, the labor substitutes for the capital of a pier. When wealthy Haitian citizens wish to board a boat without getting wet, poorer people wade through the water, carrying a client and any baggage over their heads.

Likewise, it is easy to imagine uneconomical methods for substituting capital for labor in the United States, given our prevailing cost of capital. For instance, water condensers, distillers, and tanks could substitute for those workers employed in water treatment, while grinding machines, grates, centrifuges, and incinerators could substitute for most trash collectors and sorters of recyclable wastes. Occasional labor would be involved in collecting the recycled materials.

Less extreme measures would include the automated preparation of hamburgers and of other fast foods, or the substitution of robots for lawn mowers. Because the price of capital will be more purely a function of demand instead of being a consequence of manufacturing cost, the prices of capital goods which would today be impractically expensive will fall much farther and faster than the prices of goods which already have markets.

An important consequence of this conclusion is that unemployment is a more likely outcome than it casually appears; Service economies will be transformed.

As is currently the case with software, automated manufacturers with monopoly power will have strong motivation to institute price discrimination. One of the most important ways in which markets can be distinguished is by geographic location. GPS locators, cellular network detectors, or integrated RFID tags should enable the production of complicated products which can only be used in a particular geographic area.

In this manner, computers, for instance, could be sold at one price in India and at a different price in the United States, but designed not to work outside of a designated set of low income nations. This could also be done with prescription drugs. Advanced containers could dispense unmarked pills upon demand given the proper GPS signal. Even economically depressed regions within a country could be targeted in this manner.

In a world of cheap manufacturing there will still be a place for labor-intensive high-end manufactured goods. The ability to customize designs means that made-to-order clothing can be produced by the same process used for mass produced goods, but specialists might apply their skills to adjusting designs to a particular consumer.

For instance, an expert might watch you walk in shoes with integrated sensors, then produce a prescription based on your results and order the automated production of a set of personalized shoes in a variety of styles. In general, personalized service by a variety of experts can be expected to add value for those who can pay for it. In addition, certain rare materials, such as gold, will retain their scarcity, as no economical process exists for synthesizing most elements.

Beyond manufactured goods there are of course no end to the number of physical goods, services, and abstract goods that can be both scarce and desired. Original artwork is valuable because it is in some abstract sense “original”, and would retain value even if imitations were arbitrarily precise. Land in many locations is intrinsically scarce. Pollution rights and other rights to finite commons such as hunting cannot be easily expanded through improved production.

Certain services are likely to resist the substitution of labor for capital, either because they are difficult to replace, or because they are protected by interest groups with the power and the desire to maintain scarcity. Legal services are a particularly obvious example of the latter class.

Attention is often valued for its own sake, independent of its association with any particular service. As such, attention is an intrinsically scarce good, while fame and admiration are even scarcer. If an increasing amount of effort is devoted to drawing attention, people are also likely to employ more gatekeepers, as well as technological devices such as augmented reality “spam filters” designed to screen instances of commercial speech from their awareness. After all, spam is a consequence of the inexpensive duplication of information within computers. When physically substantiated information is equally easily duplicated it will need to be screened equally aggressively.

The above economic analyses generally assume some semblance of a perfect free market. In reality, it is likely that novel regulations will be passed to moderate the impact of disruptive technologies as they arrive.

There are a number of reasons for governments to try to prevent the widespread dissemination of flexible manufacturing capabilities. The most elementary reason is to prevent the manufacture of contraband. Almost every government restricts the possession of certain goods. Although no design has yet been developed for any manufacturing system so flexible as to enable it to directly produce the majority of drugs, chemicals, weapons, etc, almost any flexible manufacturing system could be used to produce the specialized facilities required to refine opium, construct military weaponry, or culture and package anthrax.

Protection of intellectual property will be extremely difficult in the presence of flexible automated systems of manufacture, and will provide another reason for restriction.

Even if the ability to make extremely dangerous contraband is more difficult to develop in reality than it sounds (and it is worth noting how few organizations so far, even governments, have succeeded in effectively producing weaponized anthrax), existing manufacturers who see their businesses threatened are likely to publicize such dangers in order to restrict the availability of competing products manufactured with such systems.

Because distinguishing between legitimate and non-legitimate uses is so difficult, and because recognizing all of the potential misuses of a flexible technology is probably impossible, there is a natural tendency for the system to settle into an equilibrium characterized by a highly regulated and not-very innovative manufacturing industry and a highly innovative but incautious black market.

Because the manufacturing industry will be in a position to eliminate so many jobs, less wealthy citizens may find it difficult to afford the monopoly prices of authorized goods, and may turn to the black market increasingly regularly.

The tendency to do this will be minimized if a) price discrimination policies enable monopolies to sell goods for affordable prices, or b) extremely expanded industrial capacity leads to ultra-inexpensive surveillance devices which are used to find unauthorized manufacturers, convict them, and punish them severely. Because many proposed systems can be built to be very small, this surveillance would have to be very total. Investigation of its implications is beyond the scope of this paper, but I refer the reader to The Transparent Society by David Brin.