The short curing time and consequently quick healing process is advantageous for these self-healing structures with embedded healing agent reservoirs compared to many other previously reported self-healing materials. For instance, self-healing materials with microvascular networks reported by Toohey et al.18 needed to be kept at room temperature for a period of 12 hours in order to become healed. Self-healing materials with interpenetrating microvascular networks reported by Hansen et al.32 had to go under cyclic bending (50 cycles at 100 μ m displacement) to enhance the mixing of the healing agents at the location of the crack, and after that required to be subjected to 48 hours of curing at 30 °C.

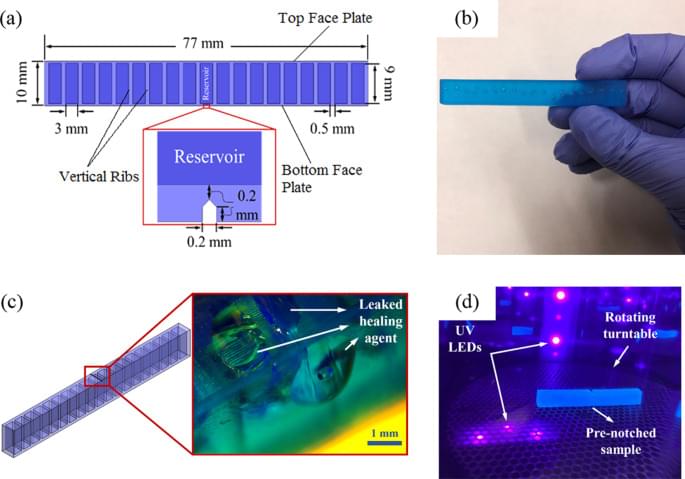

Various mechanical tests were conducted to investigate the healing capability of the structures. For each test, three identical samples with an overall dimension of 5 × 10 × 77 mm (H × W × L) were printed using a top-down SLA-based 3D printer. A notch with equal width and depth of 200 µm was incorporated in the middle of the CAD (computer aided design) model of two out of three specimens (Fig. 1a). This notch enhances the repeatability of the experiments and encourages the initiation of a straight crack under flexural (3-point bending) tests32. When a crack forms, propagates, and reaches the reservoir, the resin wicks into the crack planes as a result of capillary forces and closes the crack when it becomes cured under exposure to UV light. These forces are not high enough to drain out and deplete the large amount of healing agent in the reservoirs. The agent’s relatively high viscosity, approximately 850‑1000 cps at 25 °C, further aids in limiting its flow out of the damaged area. After healing, the specimen is tested again, and a new crack is formed under a new critical load and the aforementioned process is repeated. The small amount of leaked healing agent in the self-healing samples becomes cured relatively quickly under the UV radiation with a wavelength of 405 nm. A UV-light source was employed to cure the leaked-healing agent for 3 min. at 50 °C. To compare the effectiveness of the capillary forces for filling the crack, the notch of the second sample was manually filled before the tests. The last unnotched specimen (virgin) remained unfilled and was tested to provide a reference. It is worth noting that for simplicity’s sake, the structures were placed into a UV oven for curing; however, other types of UV sources can initiate and complete the healing process. In the case of a difficult to access part, on-site repair can be easily implemented using a remote UV source. Additionally, unloading the structure is not necessary to the healing process. A damaged structure is able to cure under loading as the healing mechanism is not affected.

The samples underwent tensile tests following the ASTM D638 standard and their force-displacement curves were recorded at a constant crosshead speed of 13 mm min−1. Figure 2 shows the force-displacement curves for each specimen type. There was a difference of 22% between the tensile fracture load of the virgin specimen without a notch and the sample that was manually repaired. By comparing the fracture force of the healed sample before and after healing (182 N for Capillary – Cycle 1 and 199 N for Capillary – Cycle 2), it can be seen that the fracture force increases by around 17 N after the sample was repaired. There is a significant difference between the fracture force of the manually repaired sample and the sample after healing (Capillary – Cycle 2). This indicates that the self-healing process is effective and is reviving the original mechanical performance of the structure.