If humankind is to explore deep space, one small passenger should not be left behind: microbes. In fact, it would be impossible to leave them behind, since they live on and in our bodies, surfaces and food. Learning how they react to space conditions is critical, but they could also be invaluable fellows in our endeavor to explore space.

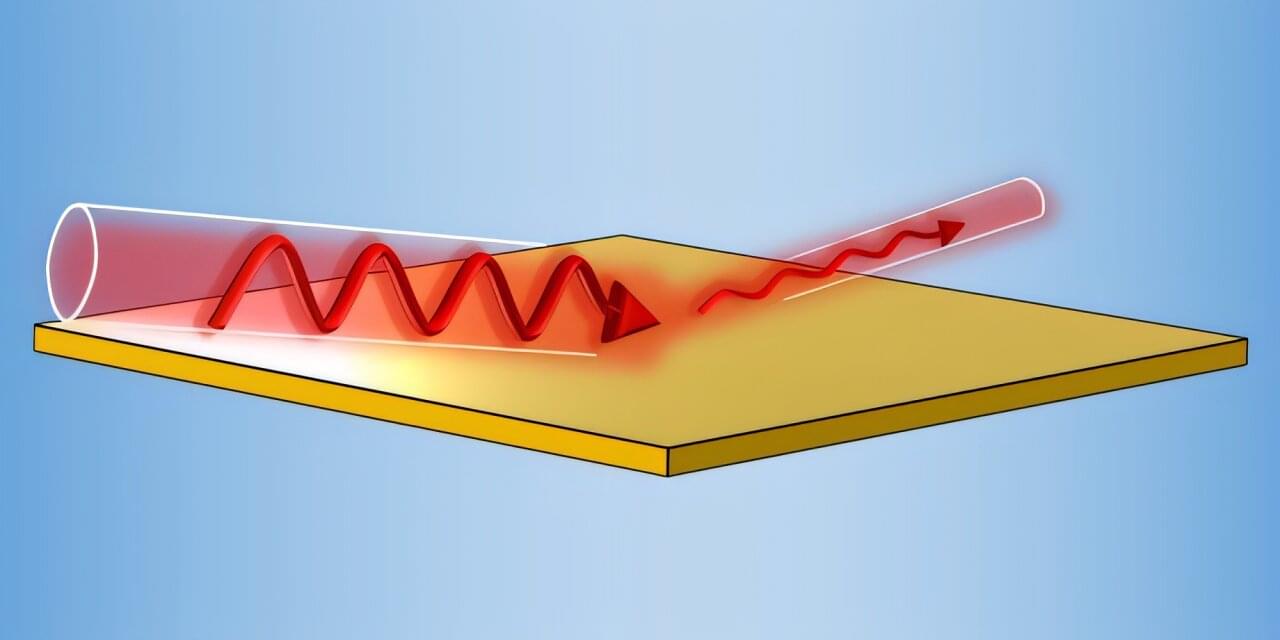

Microorganisms such as bacteria and fungi can harvest crucial minerals from rocks and could provide a sustainable alternative to transporting much-needed resources from Earth.

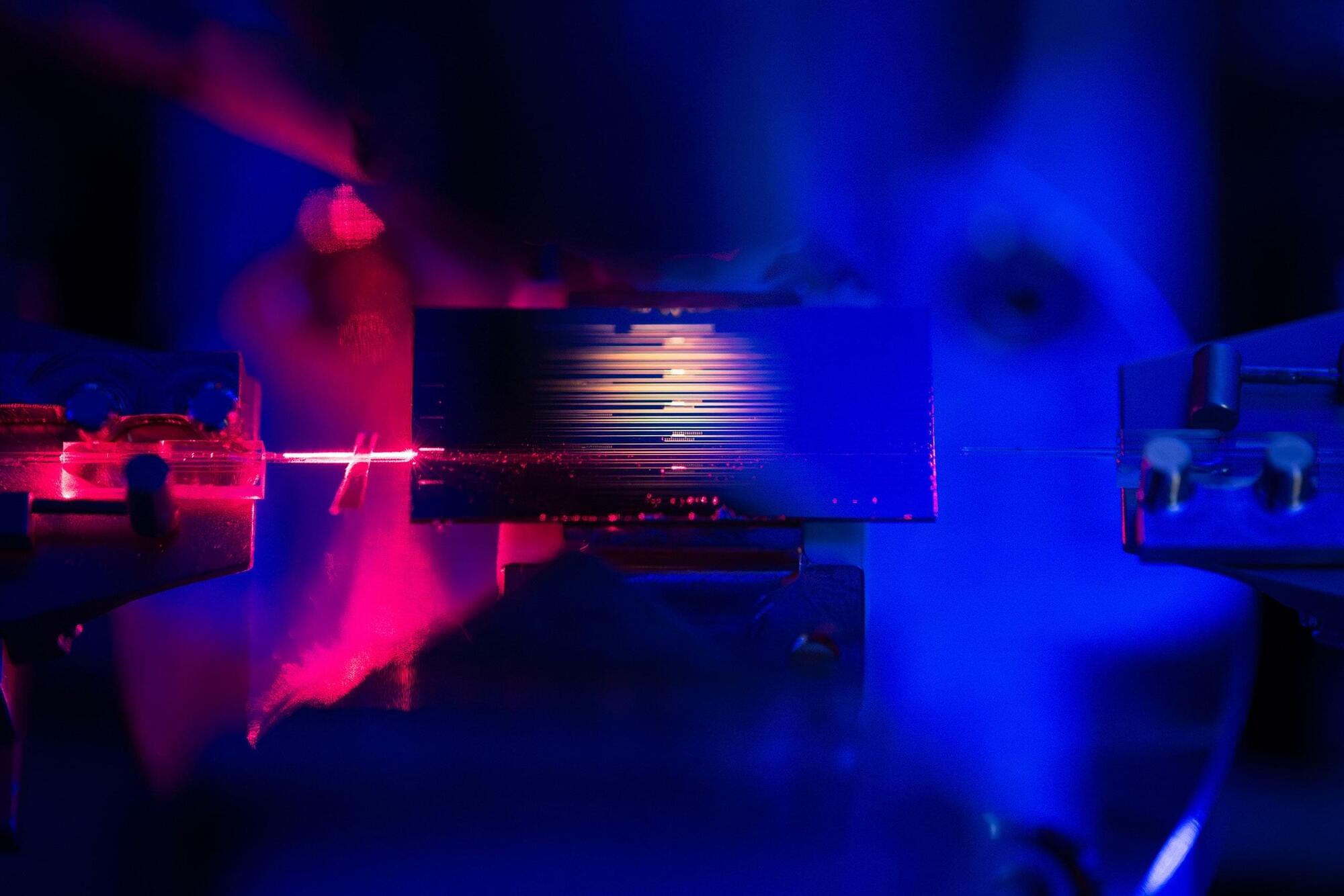

Researchers from Cornell and the University of Edinburgh collaborated to study how those microbes extract platinum group elements from a meteorite in microgravity, with an experiment conducted aboard the International Space Station. They found that “biomining” fungi are particularly adept at extracting the valuable metal palladium, while removing the fungus resulted in a negative effect on nonbiological leaching in microgravity.