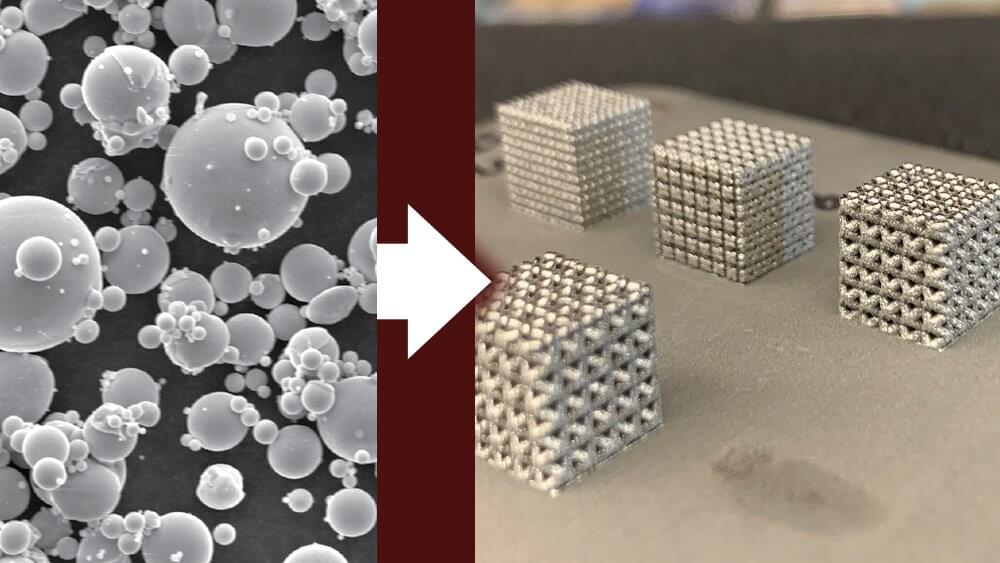

Laser powder bed fusion, a 3D-printing technique, offers potential in the manufacturing industry, particularly when fabricating nickel-titanium shape memory alloys with complex geometries. Although this manufacturing technique is attractive for applications in the biomedical and aerospace fields, it has rarely showcased the superelasticity required for specific applications using nickel-titanium shape memory alloys. Defects generated and changes imposed onto the material during the 3D-printing process prevented the superelasticity from appearing in 3D-printed nickel-titanium.

Researchers from Texas A&M University recently showcased superior tensile superelasticity by fabricating a shape memory alloy through laser powder bed fusion, nearly doubling the maximum superelasticity reported in literature for 3D printing.

This study was recently published in vol. 229 of the Acta Materialia journal.