Precious few garments have been made of spider silk. In 2012, a cape and shawl made from natural spider silk were displayed at the Victoria and Albert Museum, where visitors learned that the garments were the result of a unique project that spanned eight years and involved the harvesting of silk from 1.2 million spiders. In 2019, a rather less painstaking project utilized fibroin, the protein found in natural spider silk, to fabricate an outerwear jacket, North Face’s Moon Parka. Starting with fibroin meant that silk could be sourced from genetically modified bacteria, which are easier to work with than spiders. Nonetheless, the Moon Parka, which takes its name from the word moonshot, was never meant to be mass produced. It was available by lottery for just a limited time.

Museum pieces and moonshots are hardly synonymous with “mass production.” Is there another way to generate spider silk–based textiles, one that has more commercial potential? Yes, according to Kraig Biocraft Laboratories, which uses transgenic silkworms to produce lines of recombinant spider silk. The company plans to produce up to 10 metric tons of spider silk in 2025. Production of actual spider silk lines on this scale would allow textile manufacturers to test the silk on their own equipment.

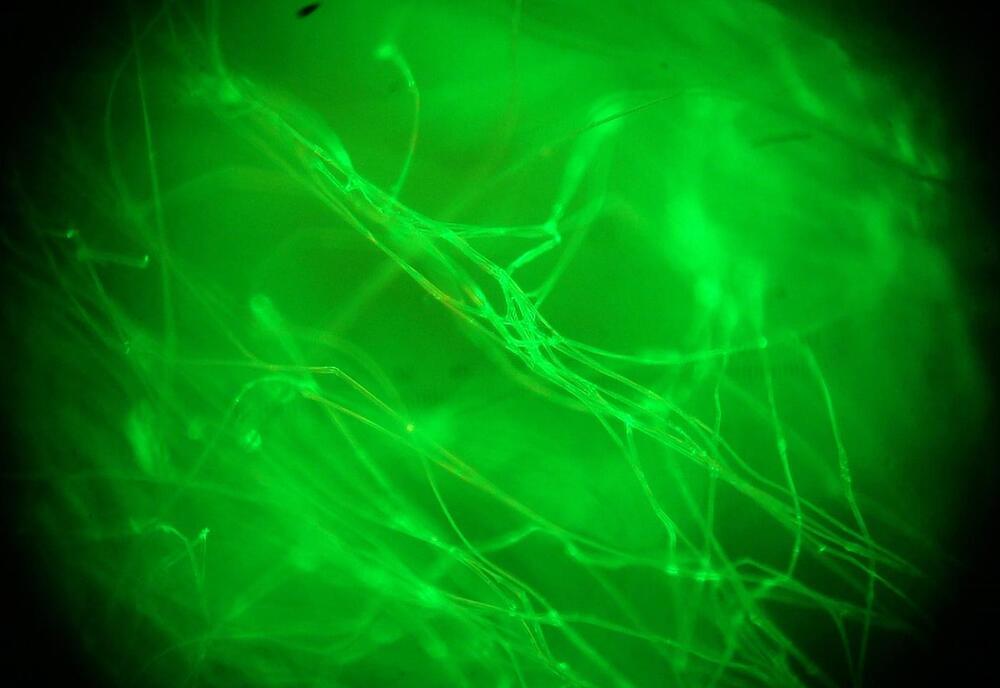

It’s not just textiles that may benefit. Recombinant spider silk’s tensile strength, weight, and durability make it attractive for myriad applications, including tissue scaffolds and sutures in the biomedical field, as well as textiles and ballistic materials.