University at Buffalo (UB) researchers have developed a novel 3D printed water-purifying graphene aerogel that could be scaled for use at large wastewater treatment plants.

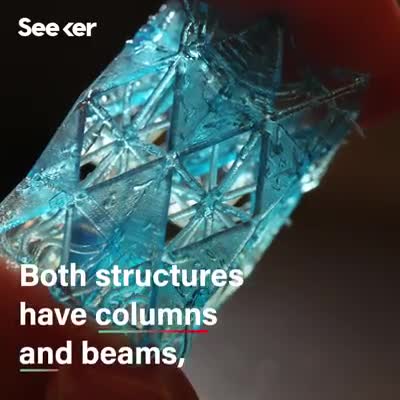

Composed of a styrofoam-like aerogel, latticed graphene and two bio-inspired polymers, the novel material is capable of removing dyes, metals and organic solvents from drinking water with 100% efficiency. Unlike similar nanosheets, the scientists’ design is reusable, doesn’t leave residue and can be 3D printed into larger sizes, thus they now aim to commercialize it for industrial-scale deployment.

“The goal is to safely remove contaminants from water without releasing any problematic chemical residue,” explained study co-author and assistant professor of environmental engineering at UB, Nirupam Aich. “The aerogels we’ve created hold their structure when put into water treatment systems, and they can be applied in diverse water treatment applications.”