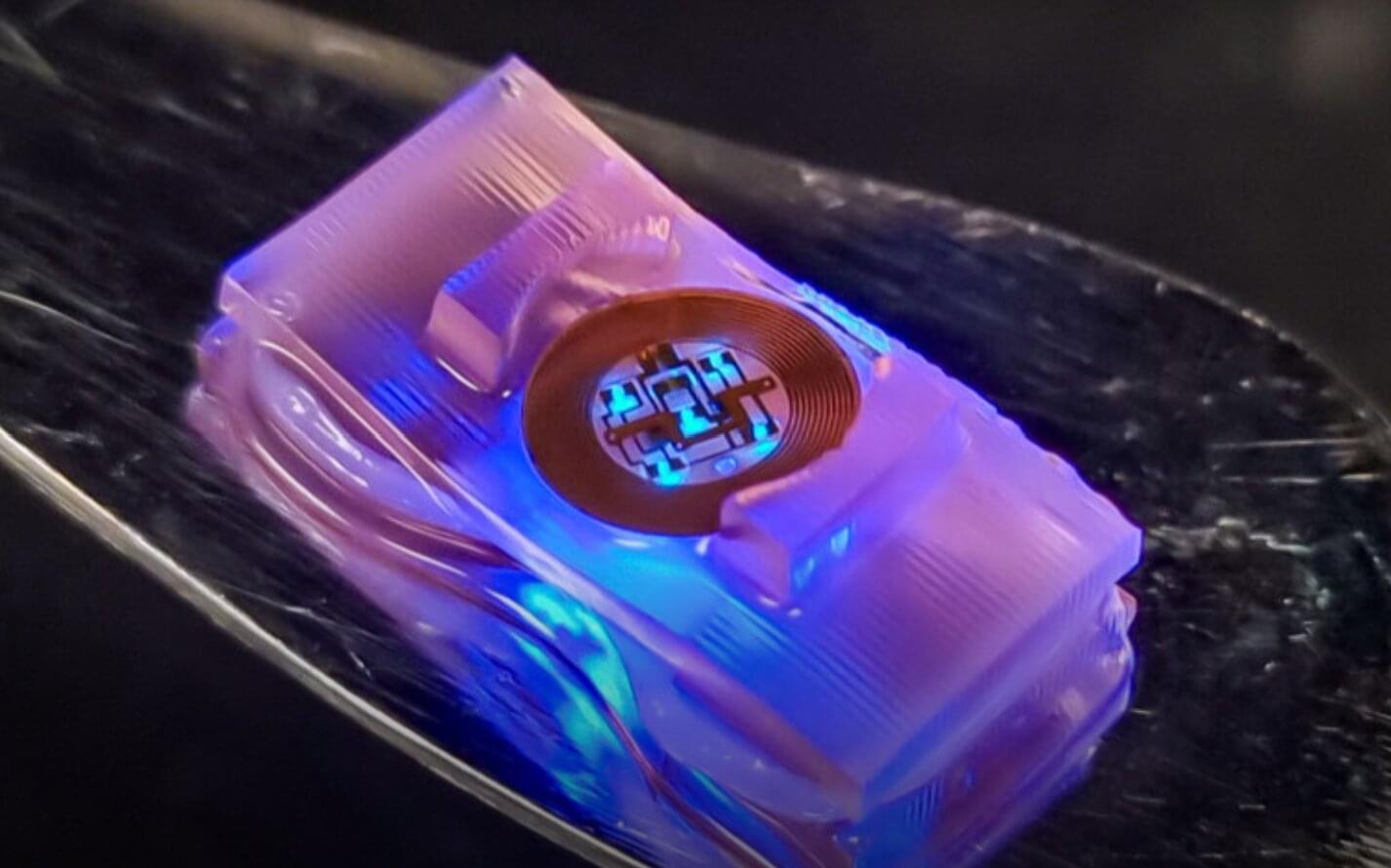

New research led by the University of Cambridge, in collaboration with Hong Kong University of Science and Technology (GZ) and Queen Mary University of London, could redefine how we interact with everyday tools and devices—thanks to a novel method for printing ultra-thin conductive microfibers.

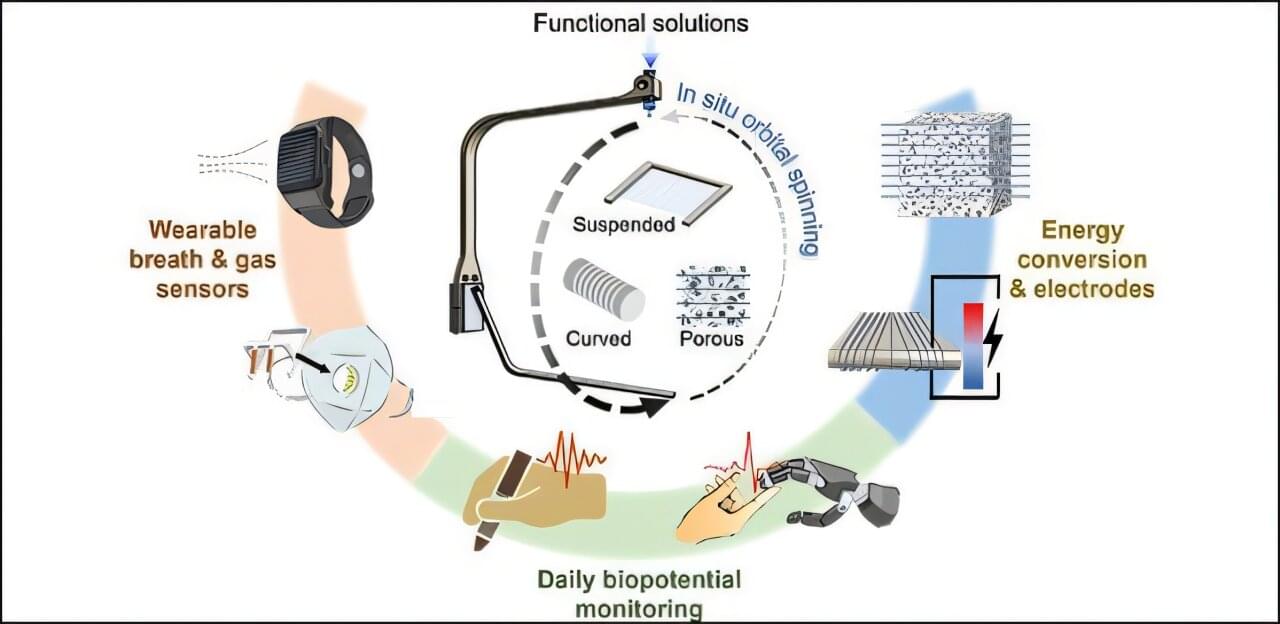

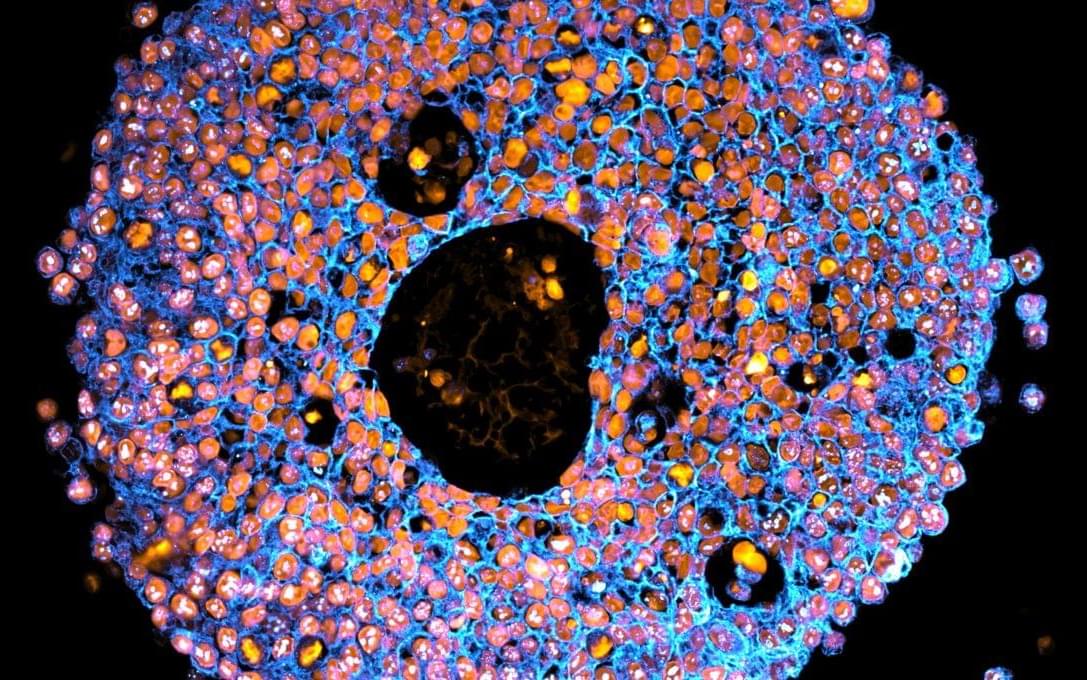

Imagine fibers thinner than a human hair (nano-to micro-scale in diameter) that can be tuned on-demand to add sensing, energy conversion and electronic connectivity capabilities to objects of different shapes and surface textures (such as glass, plastic and leather). This is what the researchers have achieved, including in unconventional materials like porous graphene aerogels, unlocking new possibilities for human-machine interaction in various everyday settings.

The researchers present a one-step adaptive fiber deposition process using 3Dprinting, set up to satisfy the fast-changing demands of users. The process enables the on-demand deployment of conductive material layers on different surface areas, dependent on the model’s geometry, at the point of use. The findings are reported in the journal Advanced Fiber Materials.