In just two years a robotic device that prints a patient’s own skin cells directly onto a burn or wound could have its first-in-human clinical trials. The 3D bioprinting system for intraoperative skin regeneration developed by Australian biotech start-up Inventia Life Science has gained new momentum thanks to major investments from the Australian government and two powerful new partners, world-renowned burns expert Fiona Wood and leading bioprinting researcher Gordon Wallace.

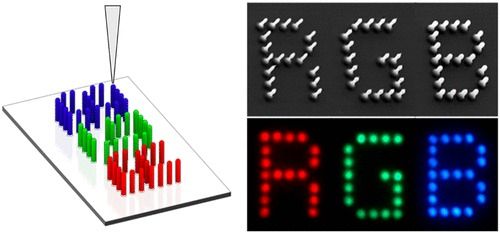

Codenamed Ligō from the Latin “to bind”, the system is expected to revolutionize wound repairs by delivering multiple cell types and biomaterials rapidly and precisely, creating a new layer of skin where it has been damaged. The novel system is slated to replace current wound healing methods that simply attempt to repair the skin, and is being developed by Inventia Skin, a subsidiary of Inventia Life Science.

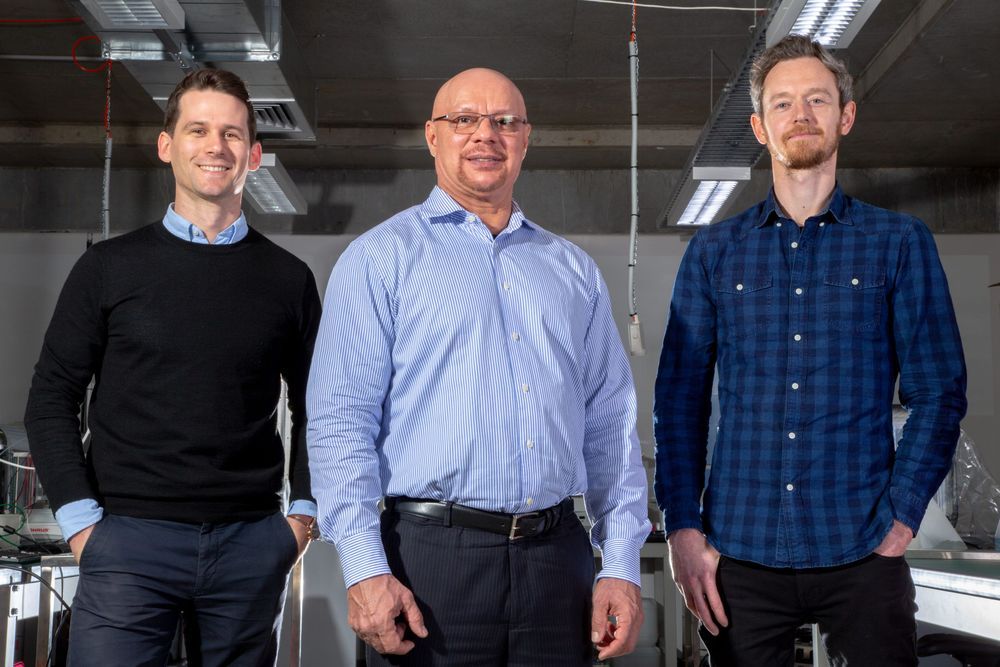

“When we started Inventia Life Science, our vision was to create a technology platform with the potential to bring enormous benefit to human health. We are pleased to see how fast that vision is progressing alongside our fantastic collaborators. This Federal Government support will definitely help us accelerate even faster,” said Dr. Julio Ribeiro, CEO, and co-founder of Inventia.