https://www.engadget.com/…/3D-printed-brain-medical-imagin…/

There are almost limitless possibilities when it comes to 3D printing. Design your own color-changing jewelry? Fine. Fabricate your own drugs? No problem. Print an entire house in under 24 hours? Sure! Now, researchers have come up with a fast and easy way to print palm-sized models of individual human brains, presumably in a bid to advance scientific endeavours, but also because, well, that’s pretty neat.

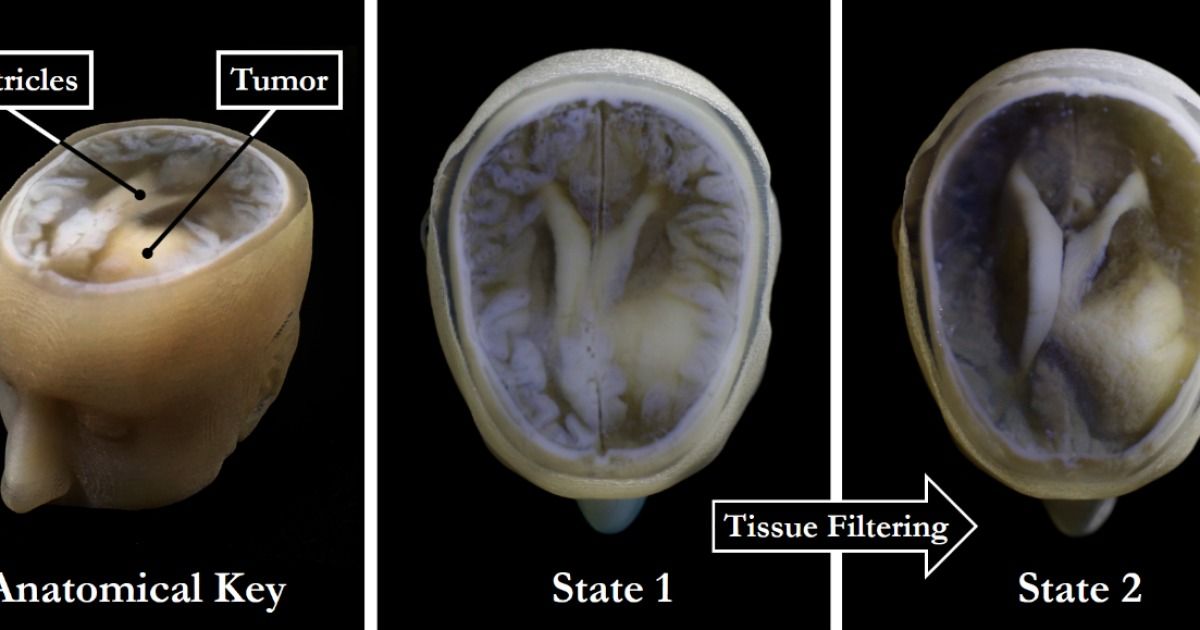

In theory, creating a 3D printout of a human brain has been done before, using data from MRI and CT scans. But as MIT graduate Steven Keating found when he wanted to examine his own brain following his surgery to remove a baseball-sized tumour, it’s a slow, cumbersome process that doesn’t reveal any important areas of interest.

MRI and CT scans produce images with so much detail that objects of interest need to be isolated from surrounding tissue and converted into surface meshes in order to be printed. This involves a radiologist manually tracing the desired object onto every single image “slice” of the brain, or it can be done via automatic thresholding, where a computer converts areas that contain grayscale pixels into either solid black or solid white pixels, based on a shade of gray that is chosen to be the threshold between black and white. But since medical imaging data often contains irregularly-shaped objects and lacks clear borders, features of interest are usually over- or under-exaggerated, and details are washed out.