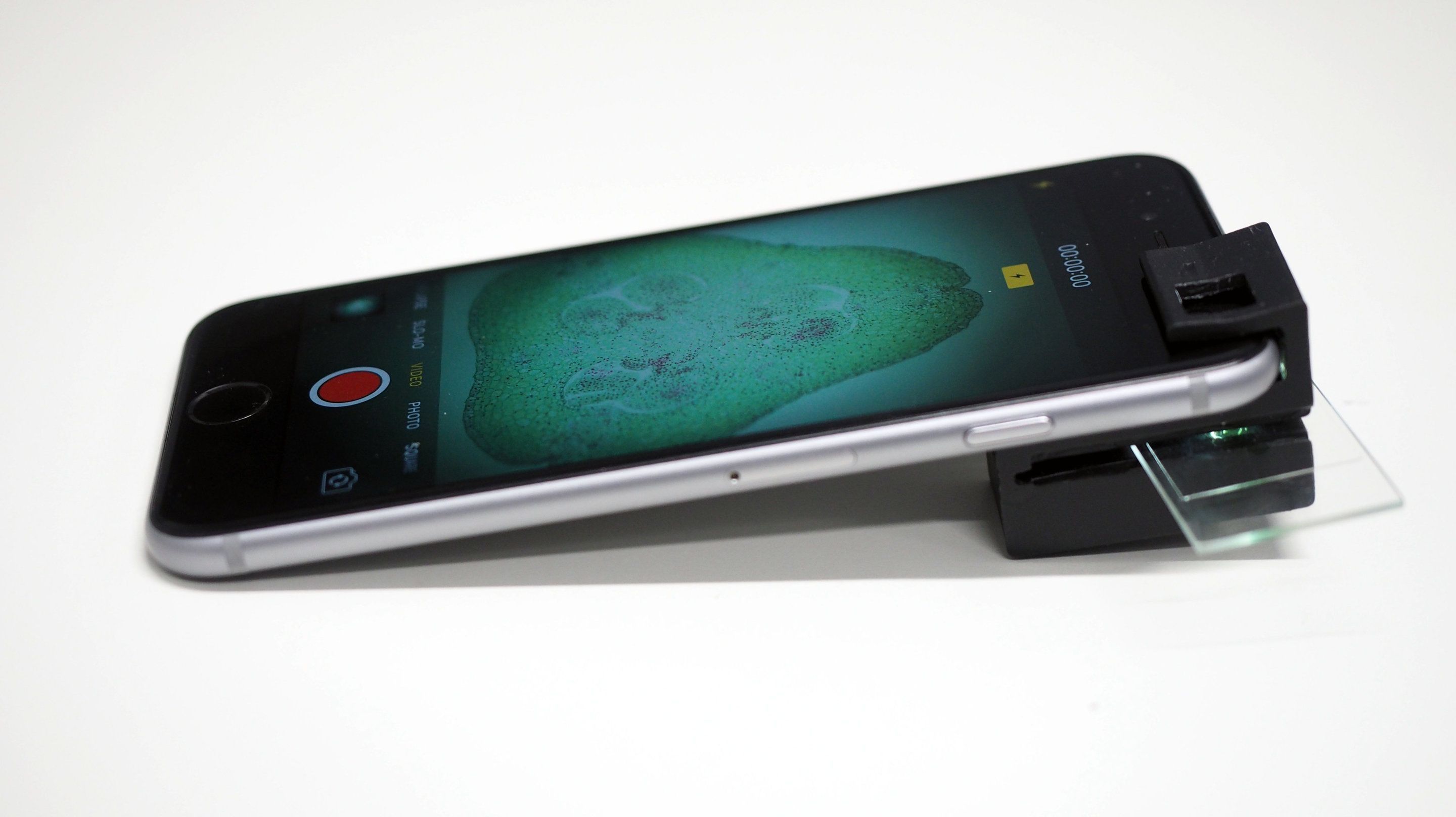

Australian researchers from the ARC Centre of Excellence for Nanoscale BioPhotonics (CNBP) have developed a 3D printable ‘clip-on’ that can turn any smartphone into a fully functional microscope.

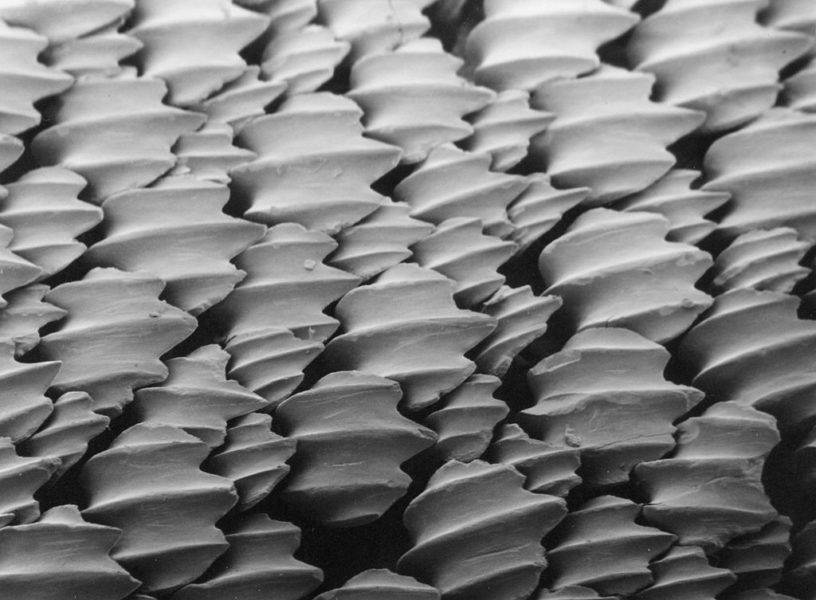

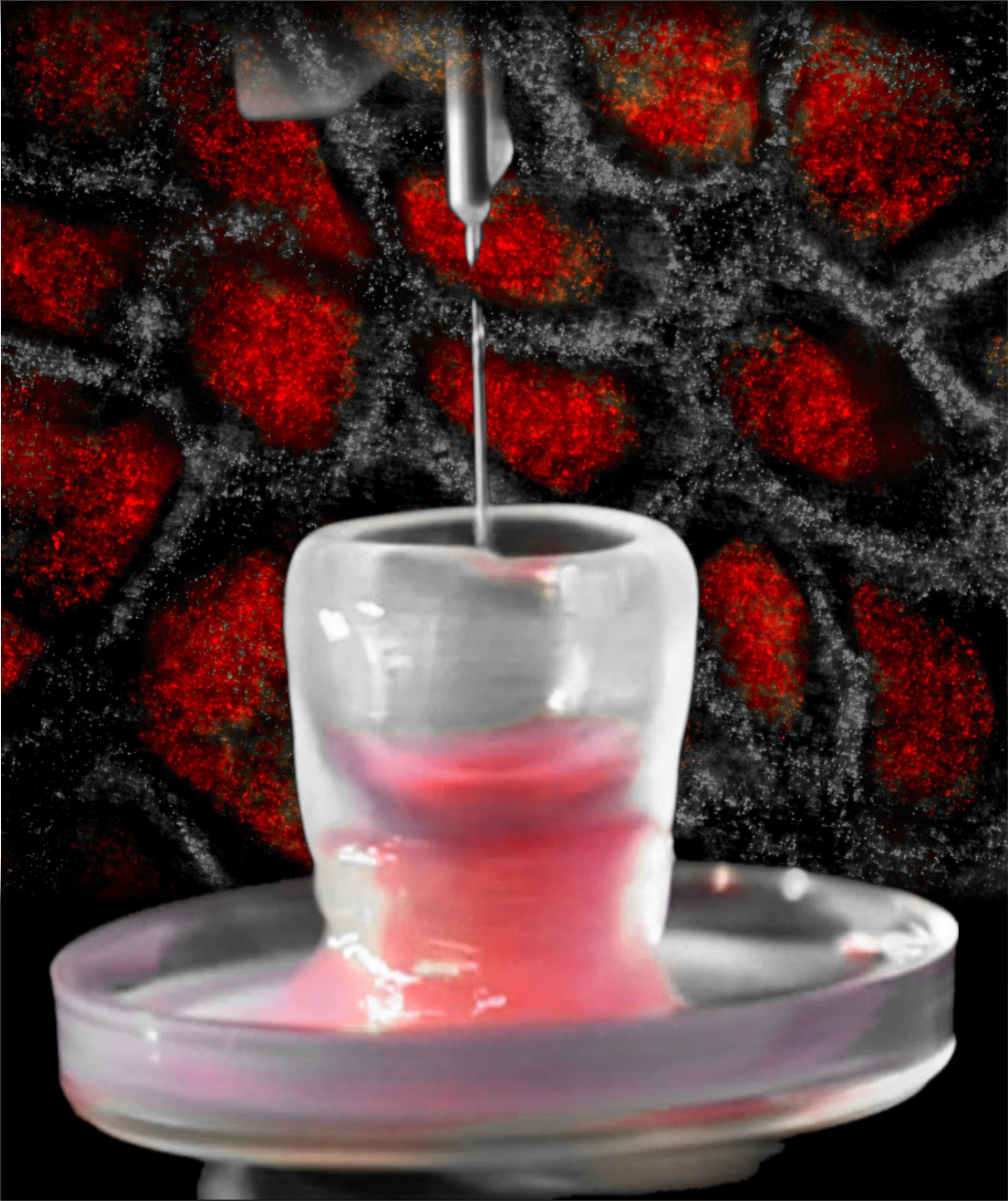

Reported in the research journal Scientific Reports, the smartphone microscope is powerful enough to visualise specimens as small as 1/200th of a millimetre, including microscopic organisms, animal and plant cells, blood cells, cell nuclei and more.

The clip-on technology is unique in that it requires no external power or light source to work yet offers high-powered microscopic performance in a robust and mobile handheld package.