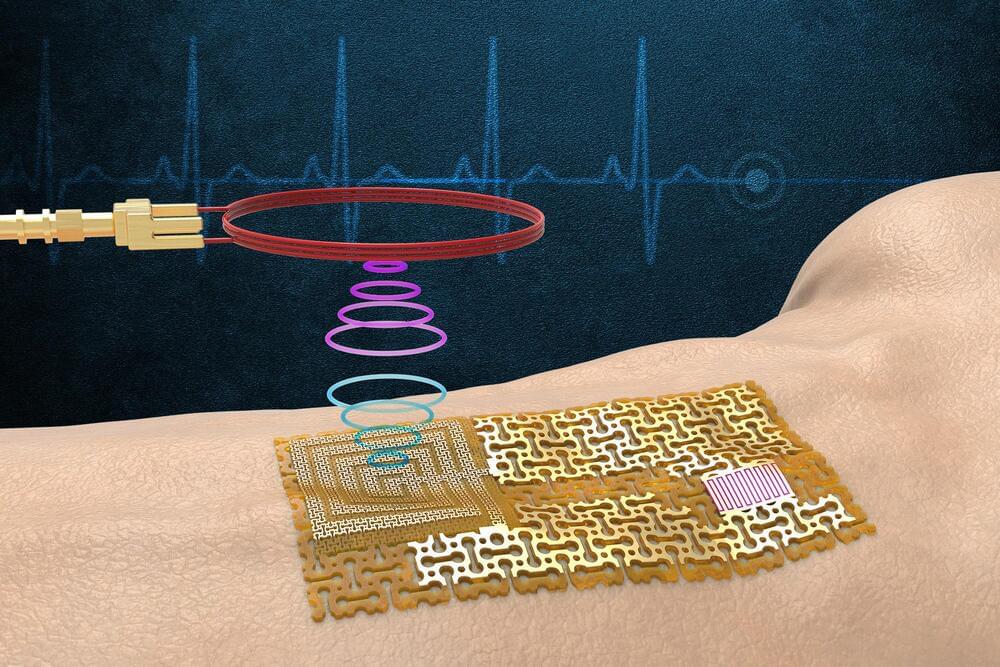

The team’s sensor design is a form of electronic skin, or “e-skin” — a flexible, semiconducting film that conforms to the skin like electronic Scotch tape. The heart of the sensor is an ultrathin, high-quality film of gallium nitride, a material that is known for its piezoelectric properties, meaning that it can both produce an electrical signal in response to mechanical strain and mechanically vibrate in response to an electrical impulse.

The researchers found they could harness gallium nitride’s two-way piezoelectric properties and use the material simultaneously for both sensing and wireless communication.

In their new study, the team produced pure, single-crystalline samples of gallium nitride, which they paired with a conducting layer of gold to boost any incoming or outgoing electrical signal. They showed that the device was sensitive enough to vibrate in response to a person’s heartbeat, as well as the salt in their sweat, and that the material’s vibrations generated an electrical signal that could be read by a nearby receiver. In this way, the device was able to wirelessly transmit sensing information, without the need for a chip or battery.