Researchers at the George Washington University have taken a major step toward reaching one of the most sought-after goals in physics: room temperature superconductivity.

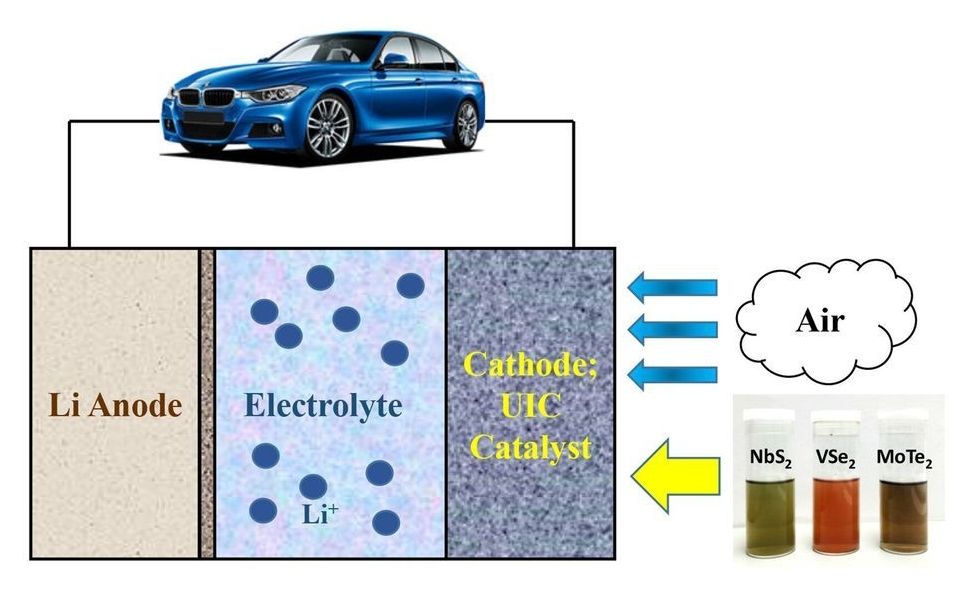

Superconductivity is the lack of electrical resistance and is observed in many materials when they are cooled below a critical temperature. Until now, superconducting materials were thought to have to cool to very low temperatures (minus 180 degrees Celsius or minus 292 degrees Fahrenheit), which limited their application. Since electrical resistance makes a system inefficient, eliminating some of this resistance by utilizing room temperature superconductors would allow for more efficient generation and use of electricity, enhanced energy transmission around the world and more powerful computing systems.

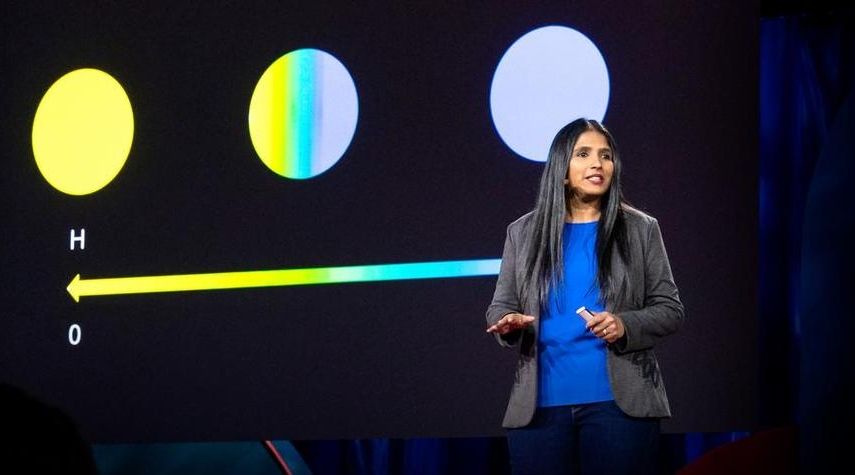

“Superconductivity is perhaps one of the last great frontiers of scientific discovery that can transcend to everyday technological applications,” Maddury Somayazulu, an associate research professor at the GW School of Engineering and Applied Science, said. “Room temperature superconductivity has been the proverbial ‘holy grail’ waiting to be found, and achieving it—albeit at 2 million atmospheres—is a paradigm-changing moment in the history of science.”