Invisibility cloak technology, real invisibility technology, military cloaking device, stealth camouflage technology, quantum stealth, cloaking device military, invisibility suit real, invisible army, military invisibility suit, DARPA cloaking tech, optical camouflage, adaptive camouflage, light bending technology, invisible tanks, real life invisibility, metamaterial invisibility, bionic camouflage, quantum invisibility cloak, future of invisibility, invisible soldier tech, battlefield invisibility, real world invisibility cloak, military stealth tech, cloaking tech 2025, thermal cloaking, active camouflage, invisibility science, invisibility suit demo, invisible armor technology, future war tech, stealth invisibility devices, camouflage that works, invisible gear military, DARPA invisibility suit, electromagnetic camouflage, AI invisibility systems, smart invisibility tech, hyperstealth material, quantum stealth suit, battlefield cloaking systems, next-gen invisibility, invisible warfare, army cloaking system, invisibility tech real, invisibility tech explained, invisibility devices 2025, invisibility war gear, invisibility prototype 2024, invisibility research military, military light bending, stealth tech evolution, invisibility in war, invisibility suit technology, military suit invisibility, invisibility fabric DARPA, smart fabric invisibility, ghost soldier tech, invisibility science real, US army invisibility trials, camouflage invisibility gear, advanced cloaking armor, invisibility cloak explained, invisibility weapons 2030, invisible battlefield weapons, stealth material real, battlefield stealth cloak, future soldier invisibility, invisibility war tools, invisibility illusion tech, invisible future soldiers, invisible force field military, adaptive invisibility suit, stealth soldier tech, military suit that vanishes, invisibility clothing military, invisibility wearable tech, invisible drone tech, war invisibility device, invisibility gear real, camouflage light bending, stealth invisibility military, invisibility lab tech, hyperstealth quantum cloak, cloaking military research, invisibility science tech, invisibility defense projects, stealth invisibility real, military invisibility breakthrough, light wave bending suit, invisibility gear 2040, DARPA invisible research, invisibility gear technology, AI and invisibility, invisibility tech future army, light bending camouflage, real invisibility breakthroughs, invisible battlefield future, invisibility innovations 2024, military invisibility progress, invisibility trials real, stealth soldier gear, invisible drone camouflage, optical stealth gear, military invisibility demonstration, real life cloaking system, invisibility advances 2025, invisibility military tech, invisible warfare future, real life invisibility suit, active invisibility devices, invisibility in modern combat, military invisibility gear, invisibility armor technology, DARPA invisibility research, quantum light bending, how invisibility works, AI cloaking tech, invisibility battle gear, invisible tanks real, stealth invisibility suit, invisible combat drones, military ghost tech, invisibility light control, invisibility gear explained, see-through military suits, invisible soldiers 2040, next gen stealth military, invisible tech in war, cloaking field devices, camouflage that hides heat, battlefield invisibility tech, science of invisibility, how cloaking tech works, invisibility gear future, invisible uniforms military, real invisibility technology, stealth invisibility explained, AI-powered invisibility, invisible weapons systems, camouflage cloaking explained, invisibility for special forces, military stealth revolution, ghost soldier tech, camouflage vs invisibility, future army invisibility, invisible armor explained, tech to disappear soldiers, invisibility in action, cloaking suit 2025, invisible gear no power, invisibility that bends light, see-through cloaking explained, invisible sniper tech, cloaking helmets army, how to become invisible, invisible war technology, future stealth camouflage, invisible body armor, invisibility tech 2040, hyperstealth cloak demo, quantum stealth explained, invisibility suit prototype, optical illusion cloaking, how metamaterials hide objects, real invisibility inventions, military invisibility projects, next level stealth tech, cloak of invisibility science, invisibility tech for defense, light-bending suit, stealth invisibility reality, invisible forces military, wearable invisibility devices, adaptive camouflage tech, AI camouflage systems, invisibility war gear, real stealth invisibility, military invisibility suit 2025, advanced cloaking tech, future of optical camouflage, invisibility field generator, invisible warfare gear, cloaking tech in real life, AI invisible armor, invisibility in science today, light manipulation technology, real invisibility cloak 2025, next-gen cloaking devices, military grade invisibility, light bending.

Category: cyborgs – Page 8

A man without a hand… now feels warmth, pressure, even pain through metal!

Bionic limbs, bionic arms, bionic legs, prosthetic limbs, prosthetic arms, prosthetic legs, artificial limbs, artificial arms, artificial legs, robotic limbs, robotic arms, robotic legs, advanced prosthetics, advanced bionics, neural prosthetics, neural interfaces, brain-computer interface, brain-machine interface, sensory feedback prosthetics, touch-sensitive prosthetics, feeling prosthetics, prosthetics with sensation, prosthetics with touch, prosthetics with feeling, prosthetics with feedback, prosthetics with sensors, prosthetics with AI, prosthetics with machine learning, prosthetics with robotics, prosthetics with neural networks, prosthetics with brain control, prosthetics with mind control, prosthetics with thought control, prosthetics with nerve control, prosthetics with muscle control, prosthetics with EMG, prosthetics with EEG, prosthetics with TMR, prosthetics with osseointegration, prosthetics with myoelectric control, prosthetics with pattern recognition, prosthetics with haptics, prosthetics with vibration feedback, prosthetics with pressure sensors, prosthetics with temperature sensors, prosthetics with force sensors, prosthetics with motion sensors, prosthetics with position sensors, prosthetics with tactile sensors, prosthetics with kinesthetic feedback, prosthetics with proprioception, prosthetics with sensory substitution, prosthetics with sensory augmentation, prosthetics with sensory restoration, prosthetics with sensory integration, prosthetics with sensory encoding, prosthetics with sensory decoding, prosthetics with sensory stimulation, prosthetics with sensory perception, prosthetics with sensory experience, prosthetics with sensory illusion, prosthetics with sensory reality, prosthetics with sensory feedback loop, prosthetics with sensory feedback system, prosthetics with sensory feedback technology, prosthetics with sensory feedback device, prosthetics with sensory feedback mechanism, prosthetics with sensory feedback method, bionic limb technology, advanced prosthetic arms, robotic limb advancements, neural-controlled prosthetics, sensory feedback in prosthetics, touch-sensitive bionic limbs, brain-machine interface prosthetics, AI-powered prosthetic limbs, next-gen prosthetics, prosthetics with real sensation, smart prosthetic technology, haptic feedback prosthetics, nerve-integrated bionic limbs, mind-controlled prosthetics, future of prosthetic limbs, prosthetic limbs with touch, innovative prosthetic designs, cutting-edge bionic arms, prosthetics with sensory input, advanced limb replacement, intelligent prosthetic systems, prosthetic limbs with AI, sensory-enabled prosthetics, high-tech prosthetic limbs, prosthetics with neural feedback, robotic prosthetics with touch, advanced bionic limb systems, prosthetic limbs with real feel, smart bionic limb technology, prosthetics with brain interface, next-generation prosthetic limbs, prosthetics with sensory technology, AI-integrated prosthetic limbs, prosthetics with real-time feedback, advanced prosthetic limb control, prosthetics with tactile feedback, intelligent bionic limb systems, prosthetics with sensory integration, prosthetic limbs with neural control, advanced prosthetic limb technology, prosthetics with sensory enhancement, smart prosthetic limb systems, prosthetics with touch feedback, AI-driven prosthetic limbs, prosthetics with real sensation technology, advanced bionic limb control, prosthetics with sensory capabilities, intelligent prosthetic limb technology, prosthetics with tactile sensation, next-gen bionic limb systems, prosthetics with neural integration, smart prosthetic limb control, prosthetics with sensory feedback systems, advanced prosthetic limb designs, prosthetics with touch-sensitive technology, AI-powered bionic limbs, prosthetics with real-time sensory feedback, intelligent bionic limb control, prosthetics with sensory response, advanced prosthetic limb interfaces, prosthetics with tactile response, smart bionic limb control, prosthetics with sensory feedback integration, AI-integrated bionic limbs, prosthetics with real-time touch feedback, advanced prosthetic limb systems, prosthetics with sensory feedback technology, intelligent prosthetic limb systems, prosthetics with tactile feedback integration, next-gen prosthetic limb technology, prosthetics with sensory feedback mechanisms, synthetic limbs with emotion, AI in prosthetic development, robotic arms with brain control, feeling-enabled prosthetic arms, bionic sense of touch, real-time neural prosthetics, prosthetic limbs that feel pain, emotion-sensing bionic limbs, tactile bionic limb feedback, smart limbs with sensory feedback, neuroprosthetics with AI, feeling through robotic hands, human-machine sensory fusion, emotional robotics prosthetics, pain-sensing artificial limbs, robotic prosthetics with emotion, neural feedback robotic limbs, brain-connected prosthetic systems, adaptive robotic prosthetic, future prosthetics with emotions.

Tilly’s bionic hand can crawl around on its own

19-year-old Instagram influencer Tilly Lockey has been at the forefront of prosthetic innovation with UK-base…

First ‘smart,’ wearable, pediatric soft exoskeleton provides mobility for children with motor difficulties

Just one look at the next-generation lightweight, soft exoskeleton for children with cerebral palsy reveals the powerful role technology can play in solving global challenges and improving lives.

Built to help children walk, MyoStep addresses motor impairments that severely restrict children’s participation in physical activities, self-care and academic pursuits, leading to developmental delays, social isolation and reduced self-esteem. It is lightweight, discreet, made of smart materials and wearable technology, and tailored to fit seamlessly into the lives of children and their families.

The MyoStep soft exoskeleton is introduced in IEEE Electron Devices Magazine by a team from the NSF UH Building Reliable Advances and Innovation in Neurotechnology (BRAIN) Center, an Industry–University Cooperative Research Center (IUCRC) and TIRR Memorial Hermann.

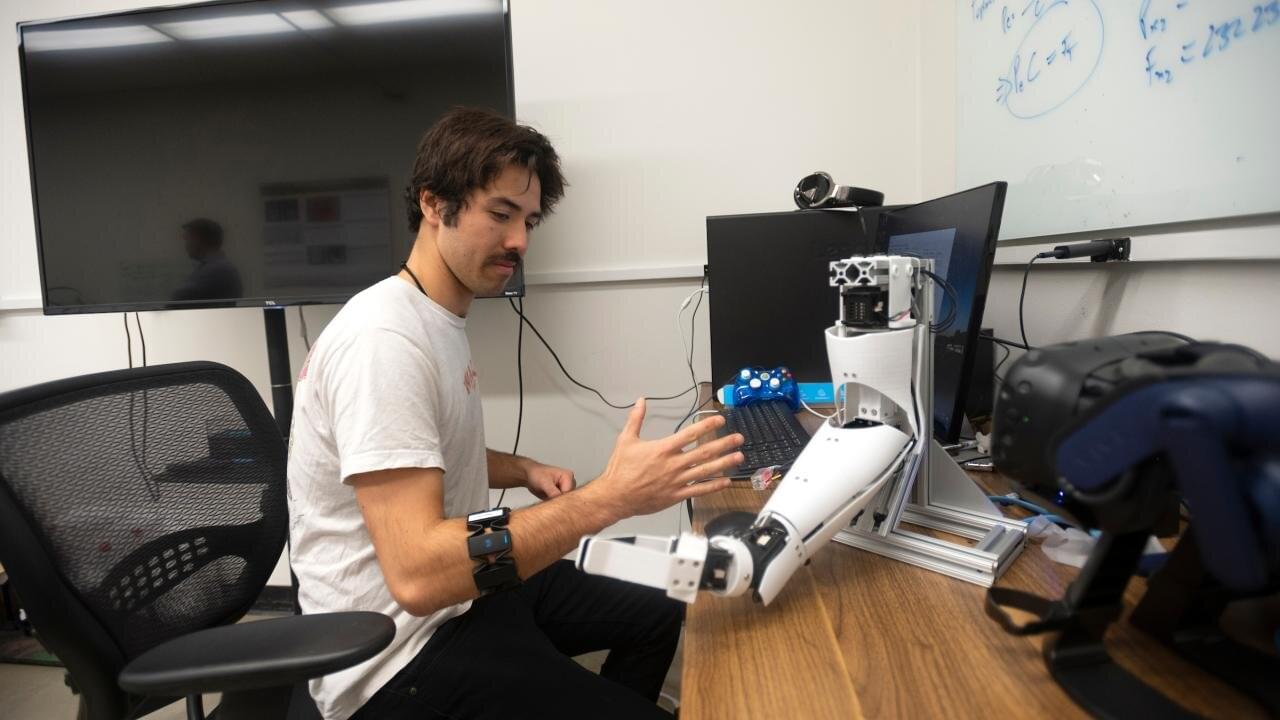

Combining electrical and force signals boosts prosthetic hand accuracy

Combining two different kinds of signals could help engineers build prosthetic limbs that better reproduce natural movements, according to a new study from the University of California, Davis. The work, published April 10 in PLOS One, shows that a combination of electromyography and force myography is more accurate at predicting hand movements than either method by itself.

The Rise of Cyborgs: Merging Man with Machine | Terrifying Future of Human Augmentation

Human cyborgs are individuals who integrate advanced technology into their bodies, enhancing their physical or cognitive abilities. This fusion of man and machine blurs the line between science fiction and reality, raising questions about the future of humanity, ethics, and the limits of human potential. From bionic limbs to brain-computer interfaces, cyborg technology is rapidly evolving, pushing us closer to a world where humans and machines become one.

Shocking transformation, futuristic nightmare, beyond human limits, man merges with machine, terrifying reality, future is now, ultimate evolution, secret experiments exposed, technology gone too far, sci-fi turns real, mind-blowing upgrade, science fiction no more, unstoppable machine man, breaking human boundaries, dark future ahead, human cyborgs, cyborg technology, cyborg implants, cyborg augmentation, cyborg evolution, cyborg future, cyborg innovations, cyborg advancements, cyborg ethics, cyborg integration, cyborg society, cyborg culture, cyborg development, cyborg research, cyborg science, cyborg engineering, cyborg design, cyborg applications, cyborg trends, cyborg news, cyborg updates, cyborg breakthroughs, cyborg discoveries, cyborg implants, bionic limbs, neural interfaces, prosthetic enhancements, biohacking, cybernetics, exoskeletons, brain-computer interfaces, robotic prosthetics, augmented humans, wearable technology, artificial organs, human augmentation, smart prosthetics, neuroprosthetics, biomechatronics, implantable devices, synthetic biology, transhumanism, bioengineering, nanotechnology, genetic engineering, bioinformatics, artificial intelligence, machine learning, robotics, automation, virtual reality, augmented reality, mixed reality, haptic feedback, sensory augmentation, cognitive enhancement, biofeedback, neurofeedback, brain mapping, neural networks, deep learning, biotechnology, regenerative medicine, tissue engineering, stem cells, gene therapy, personalized medicine, precision medicine, biomedical engineering, medical devices, health tech, digital health, telemedicine, eHealth, mHealth, health informatics, wearable sensors, fitness trackers, smartwatches, health monitoring, remote monitoring, patient engagement, health apps, health data, electronic health records, health analytics, health AI, medical robotics, surgical robots, rehabilitation robotics, assistive technology, disability tech, inclusive design, universal design, accessibility, adaptive technology, human-machine interaction, human-computer interaction, user experience, user interface, UX design, UI design, interaction design, design thinking, product design, industrial design, innovation, technology trends, future tech, emerging technologies, disruptive technologies, tech startups, tech entrepreneurship, venture capital, startup ecosystem, tech innovation, research and development, R&D, scientific research, science and technology, STEM, engineering, applied sciences, interdisciplinary research, academic research, scholarly articles, peer-reviewed journals, conferences, symposiums, workshops, seminars, webinars, online courses, e-learning, MOOCs, professional development, continuing education, certifications, credentials, skills development, career advancement, job market, employment trends, workforce development, labor market, gig economy, freelancing, remote work, telecommuting, digital nomads, coworking spaces, collaboration tools, project management, productivity tools, time management, work-life balance, mental health, wellness, self-care, mindfulness, meditation, stress management, resilience, personal growth, self-improvement, life coaching, goal setting, motivation, inspiration, success stories, case studies, testimonials, reviews, ratings, recommendations, referrals, networking, professional associations, industry groups, online communities, forums, discussion boards, social media, content creation, blogging, vlogging, podcasting, video production, photography, graphic design, animation, illustration, creative arts, performing arts, visual arts, music, literature, film, television, entertainment, media, journalism, news, reporting, storytelling, narrative, communication, public speaking, presentations, persuasion, negotiation, leadership, management, entrepreneurship, business, marketing, advertising, branding, public relations, sales, customer service, client relations, customer experience, market research, consumer behavior, demographics, psychographics, target audience, niche markets, segmentation, positioning, differentiation, competitive analysis, SWOT analysis, strategic planning, business development, growth strategies, scalability, sustainability, corporate social responsibility, ethics, compliance, governance, risk management, crisis management, change management, organizational behavior, corporate culture, diversity and inclusion, team building, collaboration, innovation management, knowledge management, intellectual property, patents, trademarks, copyrights.