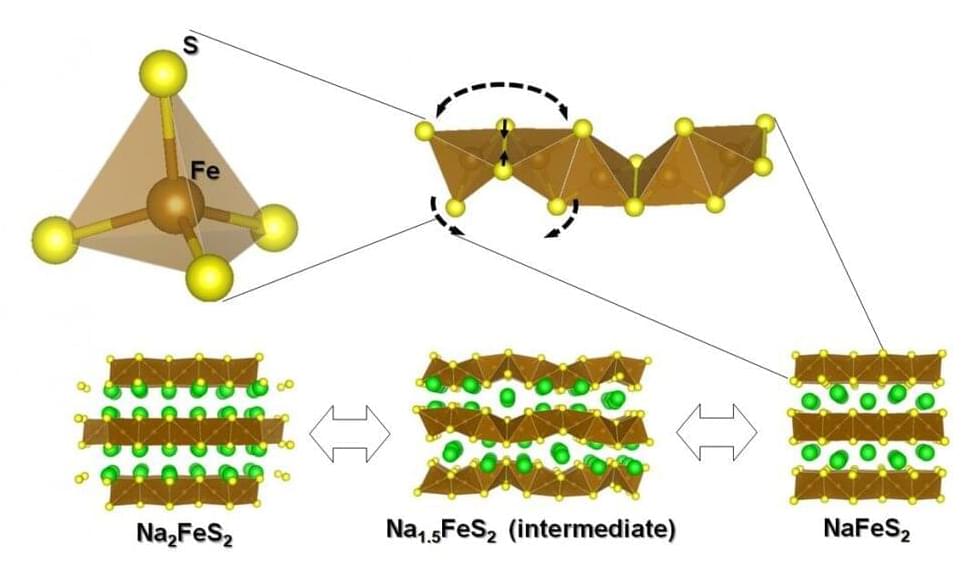

Osaka Metropolitan University scientists have successfully developed a new positive electrode material Na2FeS2, consisting of sodium, iron, and sulfur. During testing, batteries using the Na2FeS2 positive electrode had a high energy storage capacity and could be charged and discharged for more than 300 cycles. Because the Na2FeS2 is made of abundant inexpensive elements, it is expected to be used in all-solid-state sodium batteries with higher capacity and lower costs.

The demand for high energy density rechargeable batteries, such as lithium-ion batteries, increases every year, as society shifts toward becoming carbon neutral. Sodium-ion batteries—which have a resource advantage over lithium-ion batteries —are attracting more attention, as cheap new high-performance materials continue to be developed.

A research group led by Associate Professor Atsushi Sakuda, President Masahiro Tatsumisago, and Professor Akitoshi Hayashi, at the Graduate School of Engineering, Osaka Metropolitan University, has successfully developed a new positive electrode, made of Na2FeS2, for all-solid-state sodium batteries. The batteries have a high energy storage capacity, high reversibility and use inexpensive elements that are readily available.