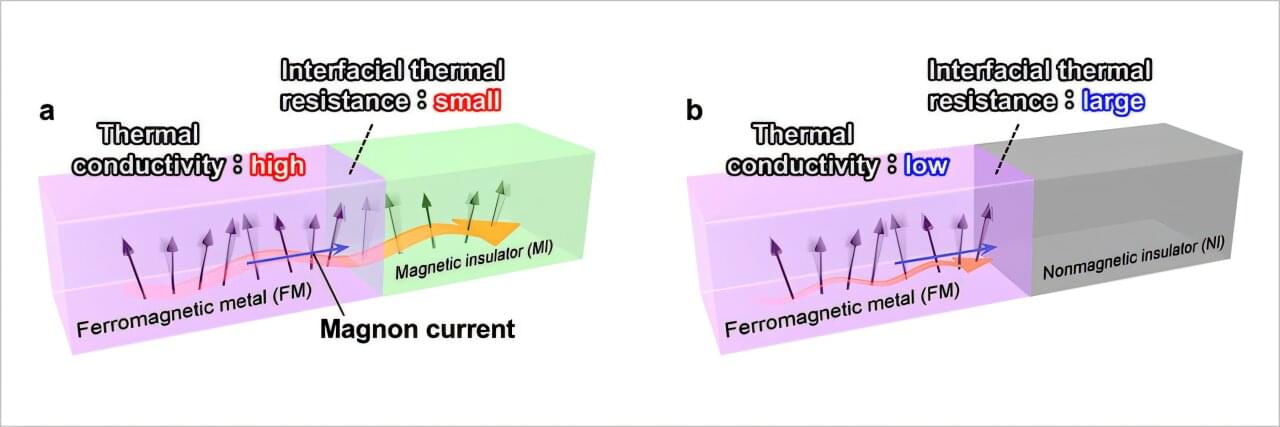

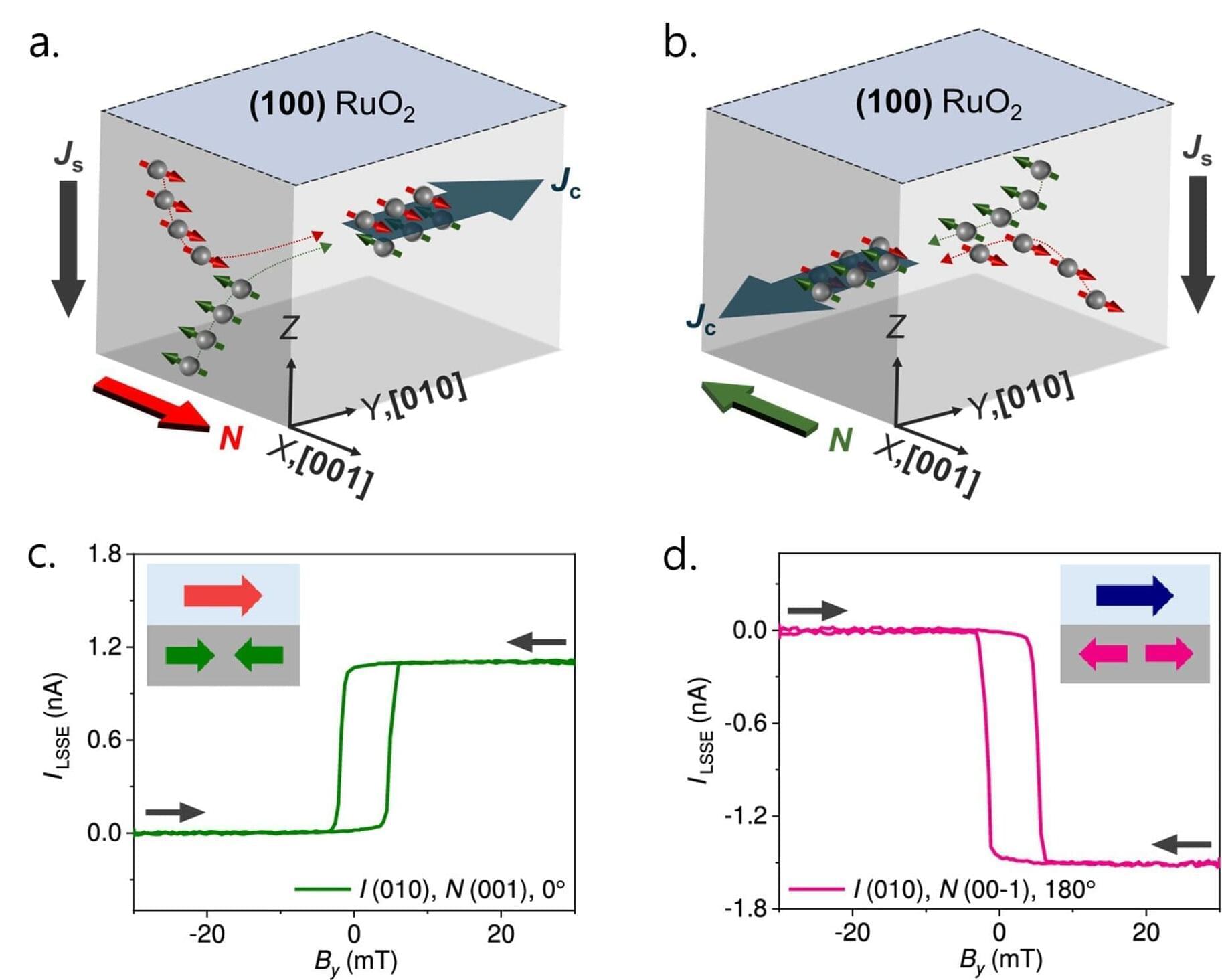

NIMS, in joint research with the University of Tokyo, AIST, the University of Osaka, and Tohoku University, have proposed a novel method for actively controlling heat flow in solids by utilizing the transport of magnons—quasiparticles corresponding to the collective motion of spins in a magnetic material—and demonstrated that magnons contribute to heat conduction in a ferromagnetic metal and its junction more significantly than previously believed.

The creation of new principles “magnon engineering” for modulating thermal transport using magnetic materials is expected to lead to the development of thermal management technologies. This research result is published in Advanced Functional Materials.

Thermal conductivity is a fundamental parameter characterizing heat conduction in a solid. The primary heat carriers are known to be electrons and phonons, quasiparticles corresponding to lattice vibrations. In current thermal engineering, efforts are underway to modulate thermal conductivity and interfacial thermal resistance by elucidating and controlling the transport properties of heat carriers. In particular, heat conduction modulation focusing on the transport and scattering of phonons has been actively studied over the past decades as “phonon engineering.”