A team of researchers at University College London, working with a colleague from Nylers Ltd. and another from XPCI Technology Ltd., has developed a new way to X-ray luggage to detect small amounts of explosives. In their paper published in the journal Nature Communications, the group describes modifying a traditional X-ray device and applying a deep-learning application to better detect explosive materials in luggage.

Prior research has shown that when X-rays strike materials, they produce tiny bends that vary depending on the type of material. They sought to take advantage of these bends to create a precision X-ray machine.

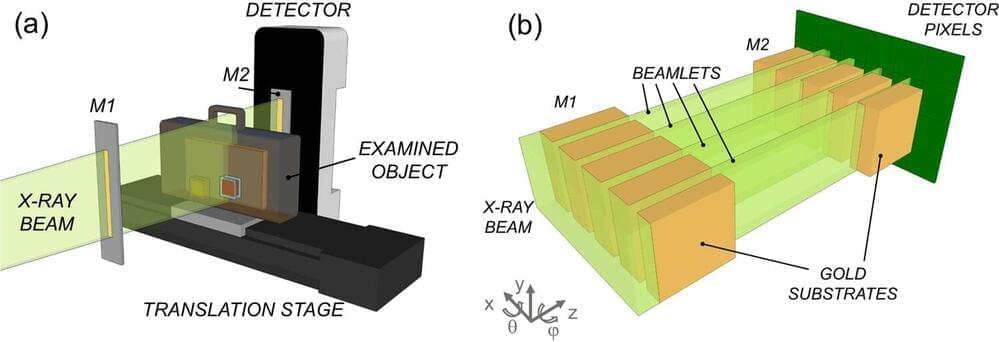

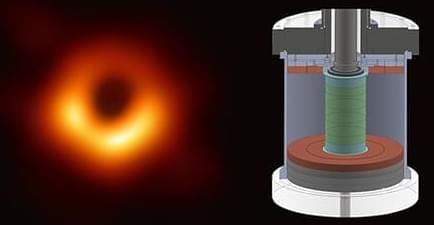

The researchers first added a small change to an existing X-ray machine—a box containing masks, which are sheets of metal with tiny holes in them. The masks serve to split the X-ray beam into multiple smaller beams. The researchers then used the device to scan a variety of objects containing embedded explosive materials and fed the results to a deep-learning AI application. The idea was to teach the machine what the tiny bends in such materials looked like. Once the machine was trained, they used it to scan other objects with embedded explosives to see if it could identify them. The researchers found their machine to be 100% accurate under lab settings.