Based on the interlocking structure of chainmail, this material has all the best parts of both solids and liquids.

Category: materials – Page 82

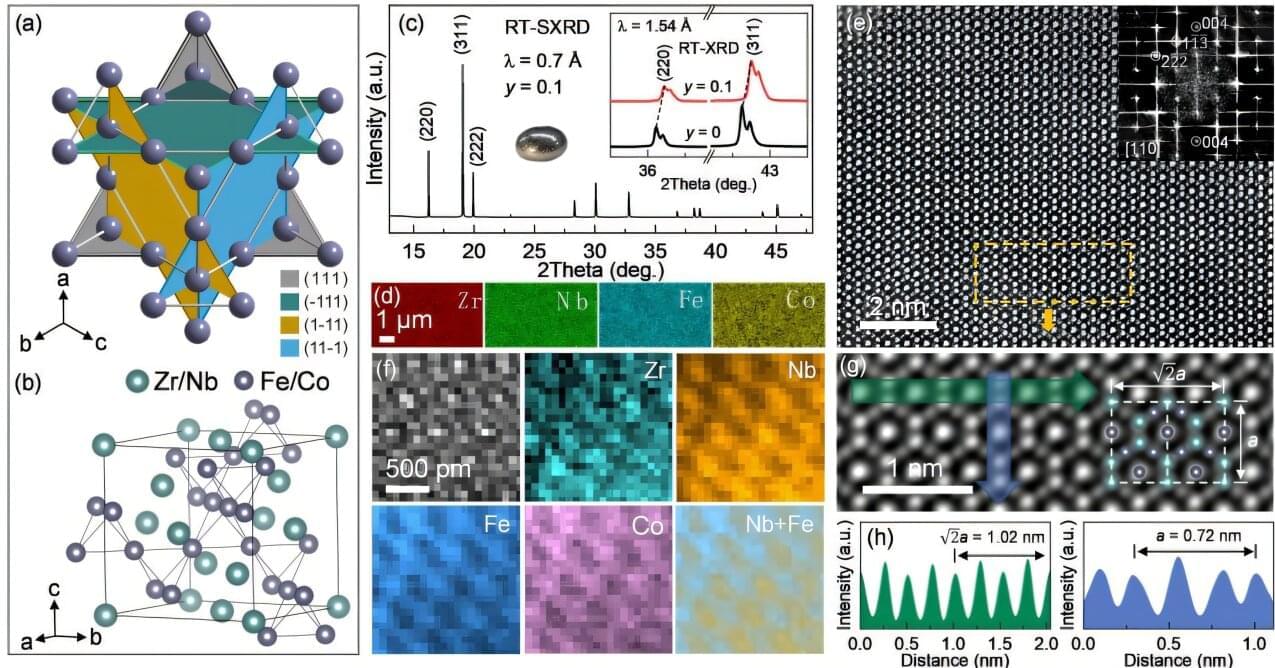

Metal alloy shows practically no thermal expansion over extremely large temperature interval

Most metals expand when their temperature rises. The Eiffel Tower, for example, is about 10 to 15 centimeters taller in summer than in winter due to its thermal expansion. However, this effect is extremely undesirable for many technical applications.

For this reason, scientists have long been searching for materials that always have the same length regardless of the temperature. Invar, for example, an alloy of iron and nickel, is known for its extremely low thermal expansion. How this property can be explained physically, however, was not entirely clear until now.

Now, a collaboration between theoretical researchers at TU Wien (Vienna) and experimentalists at University of Science and Technology Beijing has led to a decisive breakthrough.

Better digital memories with the help of noble gases

The electronics of the future can be made even smaller and more efficient by getting more memory cells to fit in less space. One way to achieve this is by adding the noble gas xenon when manufacturing digital memories.

This has been demonstrated by researchers at Linköping University in a study published in Nature Communications. This technology enables a more even material coating even in small cavities.

Twenty-five years ago, a camera memory card could hold 64 megabytes of information. Today, the same physical size memory card can hold 4 terabytes—over 60,000 times more information.

Next-Generation Spacecraft: How Caltech is Making Lightsails a Reality

“There are numerous challenges involved in developing a membrane that could ultimately be used as lightsail. It needs to withstand heat, hold its shape under pressure, and ride stably along the axis of a laser beam,” said Dr. Harry Atwater, who is a Howard Hughes Professor of Applied Physics and Materials Science at Caltech and a co-author on the study. “But before we can begin building such a sail, we need to understand how the materials respond to radiation pressure from lasers. We wanted to know if we could determine the force being exerted on a membrane just by measuring its movements. It turns out we can.”

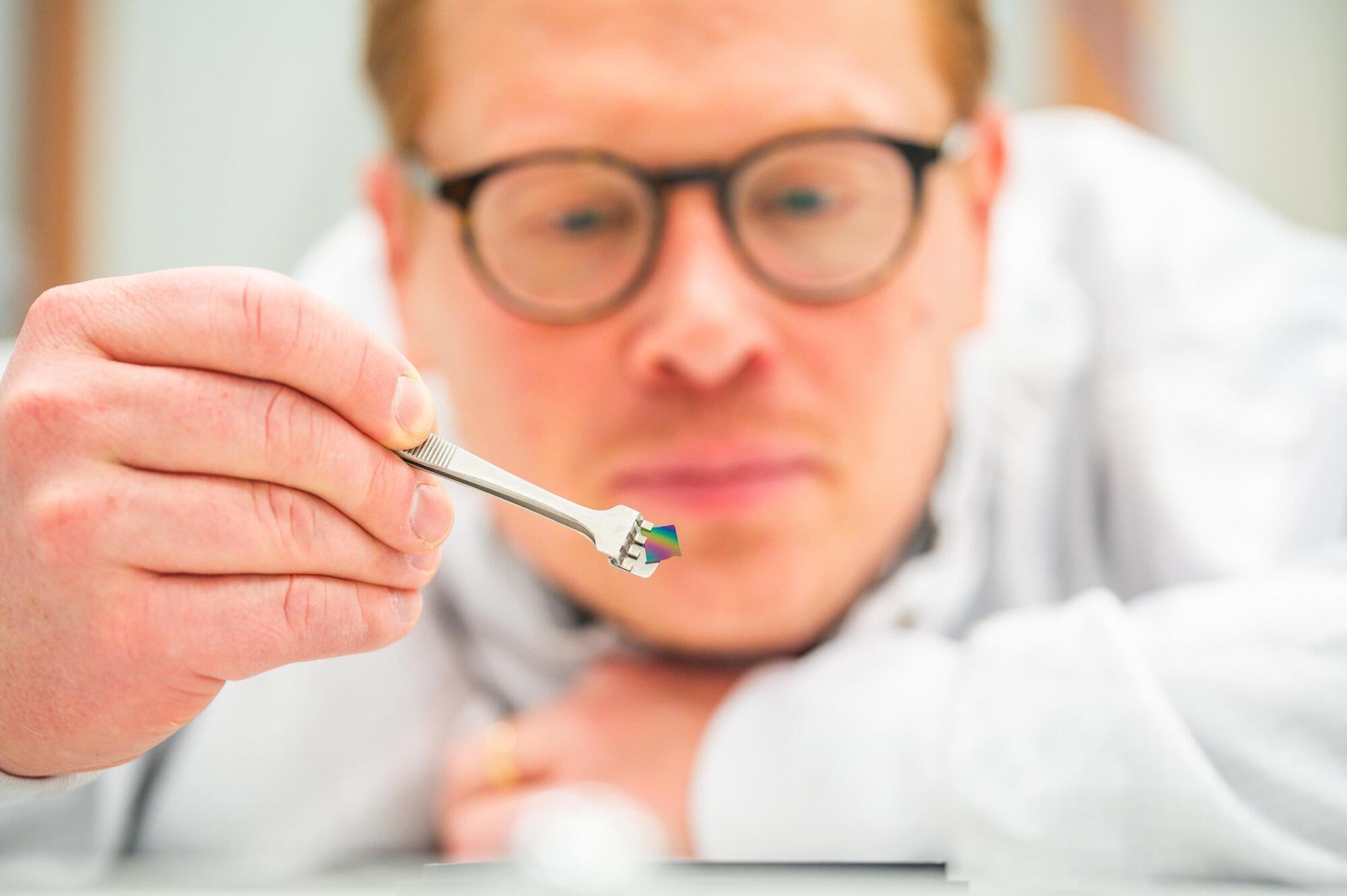

For the study, the researchers used real-life models to simulate the size of the lightsail, amount of laser power needed to propel the lightsail, and amount of pressure exerted on the lightsail to achieve the desired speed. After creating their own miniature lightsail measuring 40 microns long, 40 microns wide, and 50 nanometers thick tethered to four strings, the team subjected it to laser light to measure the amount of radiation pressure the lightsail was experiencing. In the end, the team found the specific angle and amount of force required to push the lightsail forward. Through this, they successfully established groundwork for potentially constructing larger lightsails in the future.

Improving Biosensors: Scientists Solve Significant Enzyme Challenge Using Special Material

Scientists improved enzyme-based biosensors by modifying MOFsMetal–organic frameworks (MOFs) are a new class of porous material compounds consisting of metal-to-organic ligand interactions. MOFs show promise to improve the efficiency and effectiveness of practical gas separation systems and are of interest for the storage of gases such as hydrogen and carbon dioxide. tabindex=0 MOFs to enhance electron transfer and enzyme stability.

10 Mind Blowing Recent Space Discoveries

An exploration of 10 Mind Blowing Recent Space Discoveries.

My Patreon Page:

https://www.patreon.com/johnmichaelgodier.

My Event Horizon Channel:

https://www.youtube.com/eventhorizonshow.

“The Puzzle of Meteoritic Minerals Heideite and Brezinaite; Are they Iron-based Superconductors? Are they Technosignatures?” B. P. Embaid, 2022.

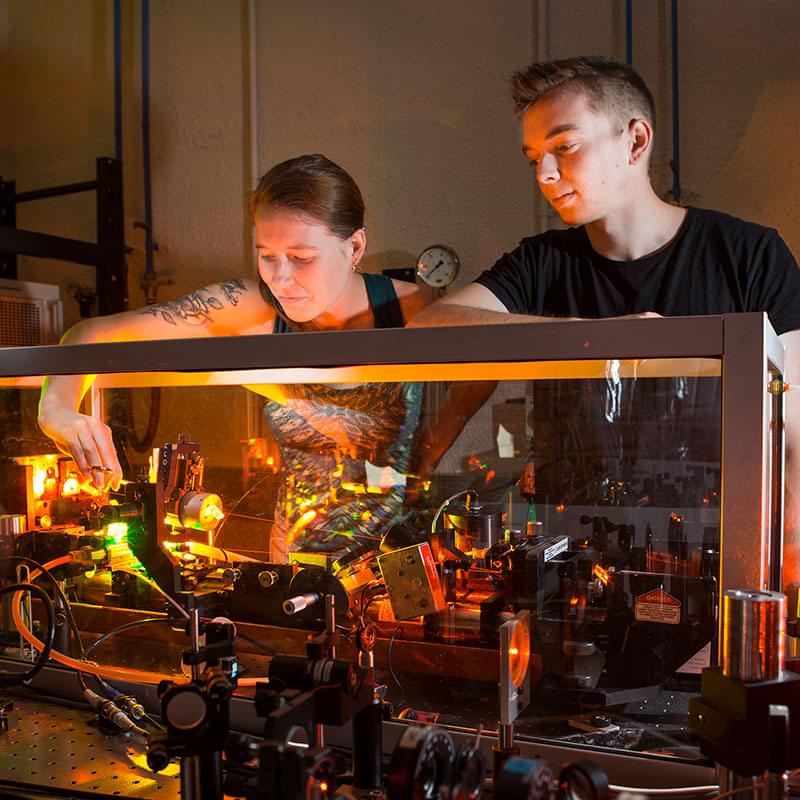

Rare earth quantum information

In our group we are researching the new materials and protocols needed for quantum communication, quantum computation and quantum sensing. The systems we use are rare earth ion crystals as they are a particularly promising candidates for building quantum information devices due to their excellent quantum coherence properties. This is crucial requirement to avoid the loss of quantum information through interactions with the local environment.

In our research we combine fundamental knowledge of the materials with the development of new quantum information protocols and device fabrication capabilities. This unique skillset has enabled us to achieve several key milestones in the field of quantum information processing, for example.

Research of the laser physics centre.

“Injectable bone” gel may be a radically better treatment for osteoporosis

Osteoporosis is typically treated with orally administered drugs, which may take up to a year to have a noticeable effect. A new injectable hydrogel, however, is claimed to drastically boost bone density in as little as two weeks.

The disease occurs when there’s an imbalance between a person’s osteoblasts – which are bone-building cells – and their osteoclasts, which are bone-degrading cells.

Ordinarily, osteoclasts serve a beneficial function by reshaping bones so they become stronger over time. When those cells outnumber the osteoblasts, though, there’s an overall loss of bone tissue, resulting in weaker, more fragile bones.

Gecko Feet Inspire New Non-Slip Polymer That Sticks to Ice

A solution to injuries from slips and falls may be found underfoot — literally. The footpads of geckos have hydrophilic (water-loving) mechanisms that allow the little animals to easily move over moist, slick surfaces. Researchers in ACS Applied Materials & Interfaces report using silicone rubber enhanced with zirconia nanoparticles to create a gecko-inspired slip-resistant polymer. They say the material, which sticks to ice, could be incorporated into shoe soles to reduce injuries in humans.

Slips and falls account for more than 38 million injuries and 684,000 deaths every year, according to the World Health Organization. And nearly half of these incidents happen on ice. Current anti-slip shoe soles rely on materials such as natural rubber that repel the layer of liquid water that sits atop pavement on a rainy day. On frozen walkways, however, shoe soles with these materials can cause ice to melt because of pressure from the wearer, creating the slippery surface the shoes are supposed to protect against.

Previous studies of gecko feet have led to new ideas for developing more effective anti-slip polymers. Those works found that their footpad’s stickiness comes from hydrophilic capillary-enhanced adhesion: The force of water being drawn into narrow grooves in the footpad creates suction that helps the lizard navigate slippery surfaces. Vipin Richhariya, Ashis Tripathy, Md Julker Nine and colleagues aimed to develop a polymer with capillary-enhanced adhesion that works on rainy sidewalks and frozen surfaces.