The battery in the Lexus UX 300e electric car is air-cooled, but Lexus is backing it up with one of the best warranties yet.

The China Electricity Council (CEC) ratified and published a set of national standards for electric vehicle wireless charging, which will be based on the magnetic resonance technology developed and patented by WiTricity, a wireless power transfer specialist based in Massachusetts.

Lack of standardization was always a major obstacle for the popularization of the wireless charging, but it seems that in the near future the industry will finally introduce a general solution for all EVs — not only in China, but also globally.

“For the past four years, WiTricity has been actively involved in the Chinese EV wireless charging standardization process through its work with China Electric Power Research Institute (CEPRI), China Automotive Technology and Research Center (CATARC) and the CEC. With a global IP portfolio of over 1400 issued and pending patents, WiTricity has declared twenty Chinese patents as ” standards essential” to systems implementing the GB standard.

Form Energy, which is developing what it calls ultra-low-cost, long-duration energy storage for the grid, has signed a contract with the Minnesota-based Great River Energy to develop a 1 megawatt, 150 megawatt hour pilot project.

The second-largest electric utility in the Minnesota, Great River Energy’s installation in Cambridge, Minn. will be the first commercial deployment of the venture-backed battery technology developer’s long-duration energy storage technology.

From Energy’s battery system is significant for its ability to deliver 1 megawatt of power for 150 hours — a huge leap over the lithium ion batteries currently in use for most grid-scale storage projects. Those battery systems can last for two- to four-hours.

Straight from the year 2029.

Tesla has patented a new battery cell with a tabless electrode that Elon Musk hypes as “way more important than it sounds.”

In the new patent application published today, Tesla explains constraints with current battery cells:

Current cells use a jelly-roll design in which the cathode, anode, and separators are rolled together and have a cathode tab and an anode tab to connect to the positive and negative terminals of the cell can. The path of the current necessarily travels through these tabs to connectors on the outside of the battery cell. However, ohmic resistance is increased with distance when current must travel all the way along the cathode or anode to the tab and out of the cell. Furthermore, because the tabs are additional components, they increase costs and present manufacturing challenges.

Wireless charging is already a thing (in smartphones, for example), but scientists are working on the next level of this technology that could deliver power over greater distances and to moving objects, such as cars.

Imagine cruising down the road while your electric vehicle gets charged, or having a robot that doesn’t lose battery life while it moves around a factory floor. That’s the sort of potential behind the newly developed technology from a team at Stanford University.

If you’re a long-time ScienceAlert reader, you may remember the same researchers first debuted the technology back in 2017. Now it’s been made more efficient, more powerful, and more practical – so it can hopefully soon be moved out of the lab.

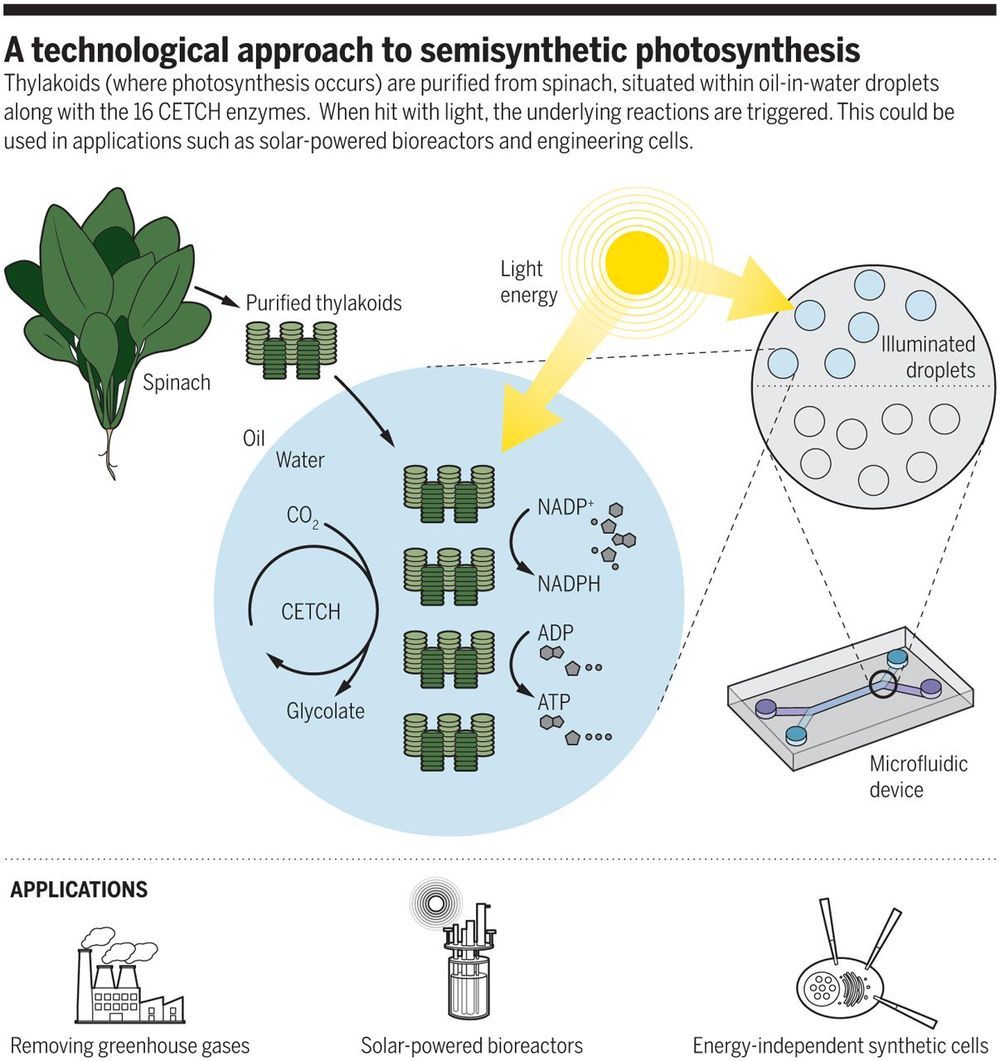

The creation of a fully artificial living cell would signify progress in both understanding current life and the development of synthetic organisms. A crucial component of any living organism is energy generation: the means to power its internal machinery. Because of their relative simplicity, catabolic reactions are the classical means for providing carbon and energy to synthetic cells, and much work has been done in optimizing which energy substrates work best for particular reactions ([ 1 ][1]). Despite robust success using small-molecule energy sources, the possibility of designing anabolic mechanisms that can harvest virtually limitless energy from light is very alluring yet remains unrealized.

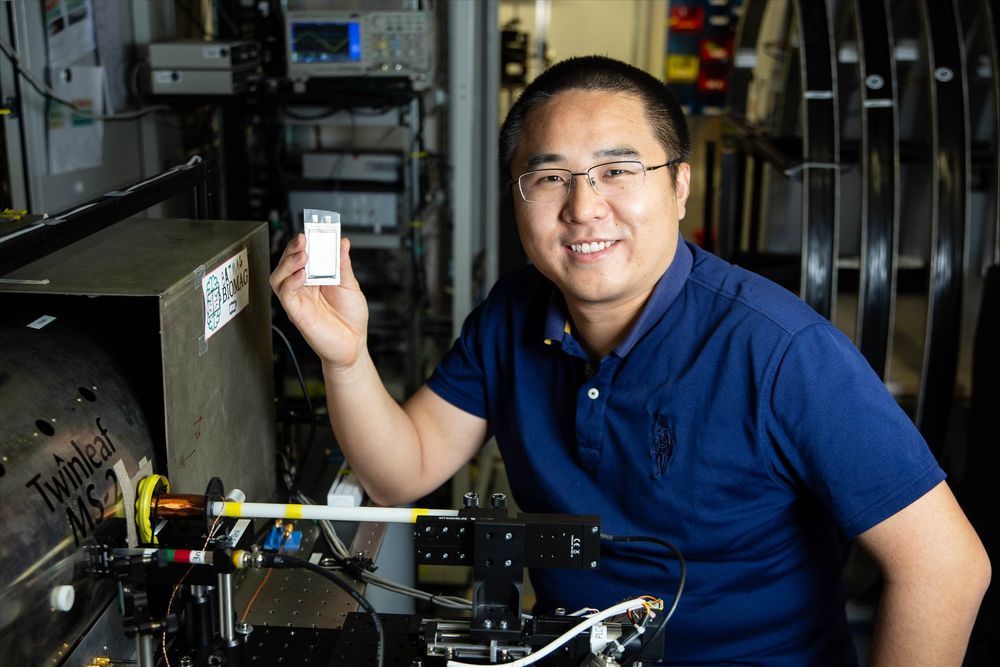

Rechargeable batteries are at the heart of many new technologies involving, for example, the increased use of renewable energies. More specifically, they are employed to power electric vehicles, cell phones, and laptops. Scientists at Johannes Gutenberg University Mainz (JGU) and the Helmholtz Institute Mainz (HIM) in Germany have now presented a non-contact method for detecting the state of charge and any defects in lithium-ion batteries. For this purpose, atomic magnetometers are used to measure the magnetic field around battery cells. Professor Dmitry Budker and his team usually use atomic magnetometry to explore fundamental questions of physics, such as the search for new particles. Magnetometry is the term used to describe the measurement of magnetic fields. One simple example of its application is the compass, which the Earth’s magnetic field causes to point north.

Non-contact quality assurance of batteries using atomic magnetometers

The demand for high-capacity rechargeable batteries is growing and so is the need for a form of sensitive, accurate diagnostic technology for determining the state of a battery cell. The success of many new developments will depend on whether batteries can be produced that can deliver sufficient capacity and a long effective life span. “Undertaking the quality assurance of rechargeable batteries is a significant challenge. Non-contact methods can potentially provide fresh stimulus for improvement in batteries,” said Dr. Arne Wickenbrock, a member of Professor Dmitry Budker’s work group at the JGU Institute of Physics and the Helmholtz Institute Mainz. The group has achieved a breakthrough by using atomic magnetometers to take measurements. The idea came about during a teleconference between Budker and his colleague Professor Alexej Jerschow of New York University. They developed a concept and, with close cooperation between the two groups, carried out the related experiments in Mainz.