The German automaker uses new software from chipmaker Nvidia to simulate train robots and human workers.

Could be used for next generation electric cars.

The British appliance manufacturer Dyson claims to have developed the world’s fastest, most efficient motor for domestic appliances. The Dyson Digital Motor (DDM) v2 is a single-phase brushless DC motor, which operates at speeds up to 104000 rpm with a claimed efficiency of 84%.

Dyson’s first digital motor, announced in 2003, used switched reluctance technology.

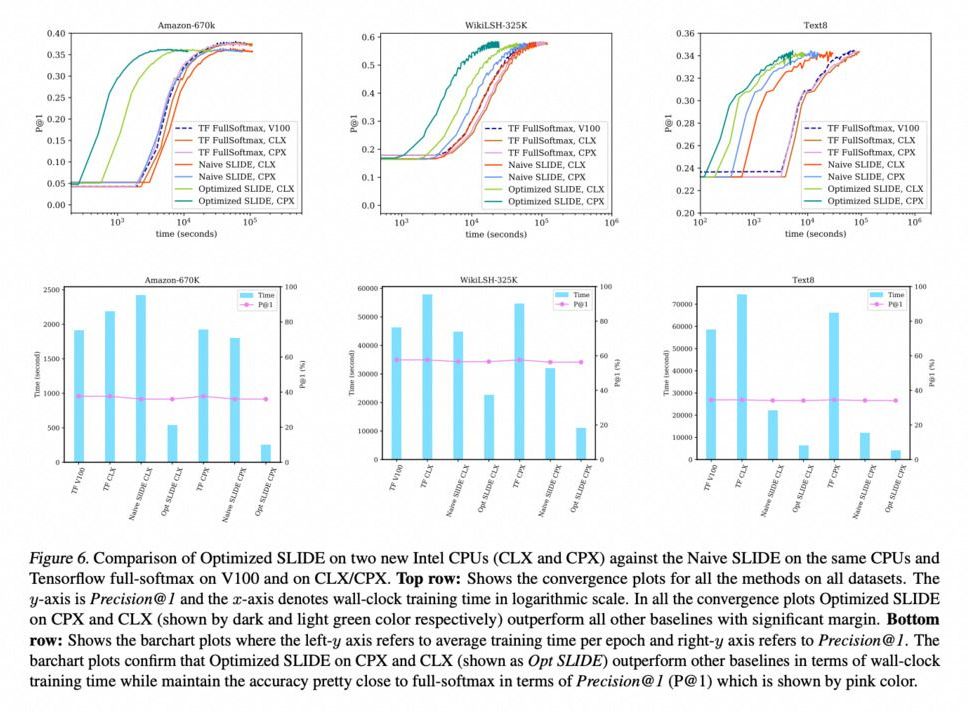

Computer scientists from Rice University have displayed an artificial intelligence (AI) software that can run on commodity processors and train deep neural networks 15 times faster than platforms based on graphics processors.

According to Anshumali Shrivastava, an assistant professor of computer science at Rice’s Brown School of Engineering, the resources spent on training are the actual bottleneck in AI. Companies are spending millions of dollars a week to train and fine-tune their AI workloads.

Deep neural networks (DNN) are a very powerful type of artificial intelligence that can outperform humans at some tasks. DNN training is a series of matrix multiplication operations and an ideal workload for graphics processing units (GPUs), which costs nearly three times more than general-purpose central processing units (CPUs).

Rice University computer scientists have demonstrated artificial intelligence (AI) software that runs on commodity processors and trains deep neural networks 15 times faster than platforms based on graphics processors.

“The cost of training is the actual bottleneck in AI,” said Anshumali Shrivastava, an assistant professor of computer science at Rice’s Brown School of Engineering. “Companies are spending millions of dollars a week just to train and fine-tune their AI workloads.”

Shrivastava and collaborators from Rice and Intel will present research that addresses that bottleneck April 8 at the machine learning systems conference MLSys.

Segway-Ninebot has rather sensationally announced that it’s building a hydrogen fuel cell sportsbike – and boy does this thing look like it glitched its way out of Cyberpunk 2077, complete with a highly improbable steering design and an amazing price.

Here’s what we know so far: Segway has been playing with performance bikes a little bit lately to go with its lineup of cheap electric scooters, mainly sold in China. The Apex was announced in 2019, a slightly gawky looking battery-electric “super scooter” capable of 125 mph (200 km/h), with full sportsbike fairings.

Now, there’s an Apex H2 coming, which will run a hydrogen-electric hybrid powertrain – gaseous hydrogen stored in tanks will be converted into electrical energy through a fuel cell and fed into a buffer battery, which will power an electric motor that drives the rear wheel in some way or another – we can’t see whether there’s a chain drive or a hub motor or what indeed is going on in these renders. Yes, that’s an exhaust port in front of the rear wheel, but all that’ll be coming out of it is water vapor.

In the future, Tesla’s Autopilot and Full Self-Driving suite are expected to handle challenging circumstances on the road with ease. These involve inner-city driving, which includes factors like pedestrians walking about, motorcyclists driving around cars, and other potential edge cases. When Autopilot is able to handle these cases confidently, the company could roll out ambitious projects such as Elon Musk’s Robotaxi Network.

Tesla’s FSD Beta, at least based on videos of the system in action, seems to be designed for maximum safety. Members of the first batch of testers for the FSD Beta have shared clips of the advanced driver-assist system handling even challenging inner-city streets in places such as San Francisco with caution. But even these difficult roads pale in comparison to the traffic situation in other parts of the world.

In Southeast Asian countries such as Vietnam, for example, traffic tends to be very challenging, to the point where even experienced human drivers could experience anxiety when navigating through inner-city roads. The same is true for other countries like India or the Philippines, where road rules are loosely followed. In places such as these, Autopilot still has some ways to go, as seen in a recently shared video from a Tesla Model X owner.

This is the only solely ion propelled series of aircrafts that can lift their power supplies against earth’s gravity. These prototypes were patented specifically for lifting their onboard power supplies and the widely published patent has been in effect since 2014.

While the craft wasn’t working at full power for this test footage since their was a power loss, the safety tether still went completely loose when the craft was energized, and it is also shown flying outdoors. There is an indoor flight that lasted for almost 2 minutes continually when it was flying at its best. There is a video of that and other sustained flights on this YouTube channel.

Previously all heavier than air ion propelled aircrafts had to be connected through thin wires to large heavy power supplies that remained fixed to the ground.

This series of prototypes have been independently verified to fly with onboard power since 2006. It was necessary to increase the EAD thrust to weight ratio by several orders of magnitude as well as other upgrades to get it operational.

Here is a link to a broadcast about the craft with the host of NPR Jeff Saint Clair. His article and radio program certifies fist hand, that this ion propelled aircraft US Patent number 10119, 527, lifts its power supply:

https://radio.wosu.org/post/exploradio-oberlin-inventor-push…t#stream/0

Sorry, we’re having trouble playing this video.

Learn More.

World Economic Forum.

· YtesiStSrfpserrfenfduaySh atmso hcn9:snet00r orAeMd ·

AI, self-driving cars, robotics and more… all in one place.

Find out more about our upcoming Global Technology Governance Summit: #GT… See More.