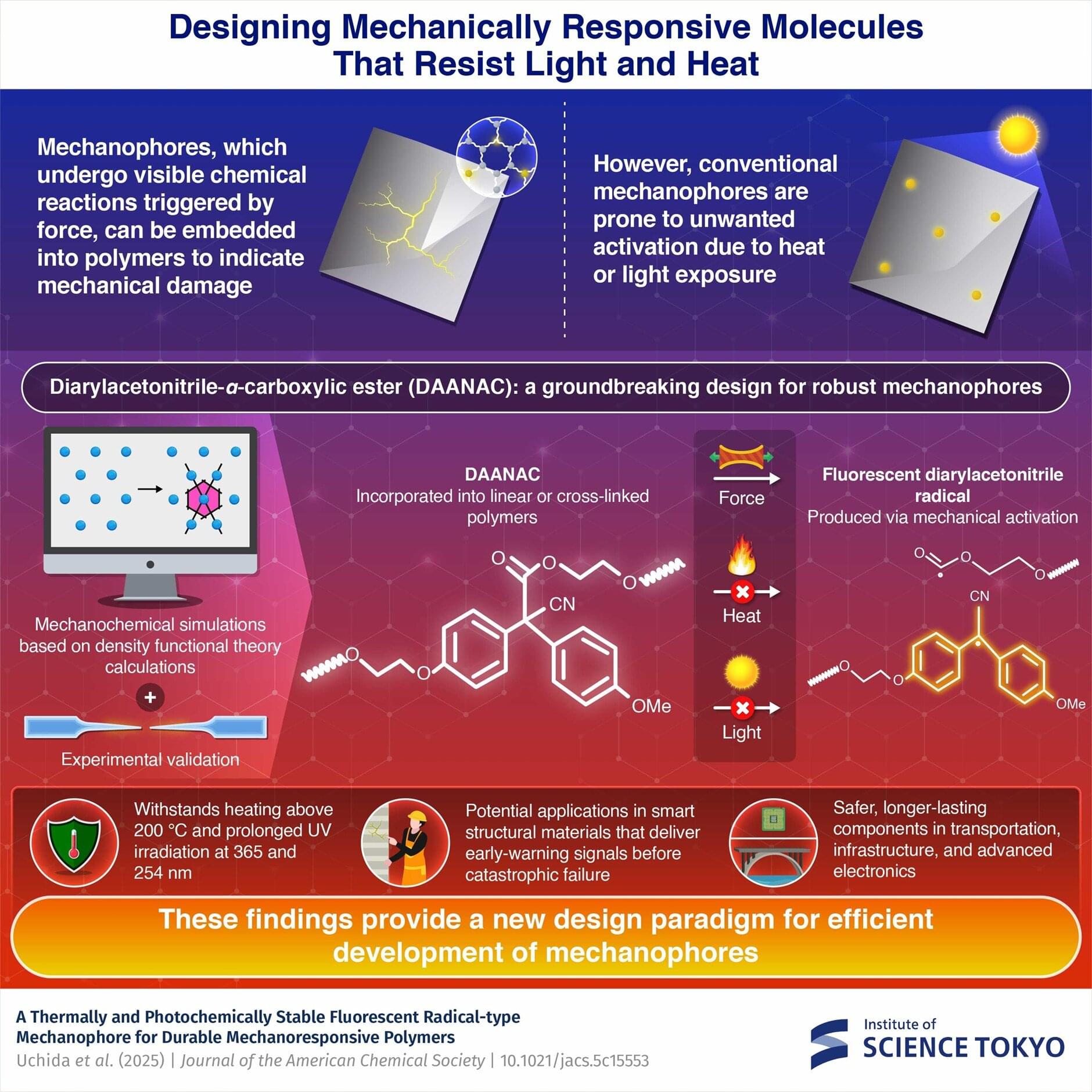

A newly designed robust mechanophore provides early warning against mechanical failure while resisting heat and UV, report researchers from Institute of Science Tokyo. They combined computational chemistry techniques with thermal and photochemical testing to show that their mechanophore scaffold, called DAANAC, stays inert under environmental stress yet emits a clear yellow signal when mechanically activated. This could pave the way for smart, self-reporting materials in construction, transportation, and electronics.

High-performance polymers, such as plastics and elastomers, are essential materials in modern life that are present in everything from airplane parts to bridges and electronics. Because sudden failures in these sectors can be extremely dangerous and costly, ensuring the safety and longevity of high-performance polymers is a critical challenge.

Since damage is often invisible at the molecular level until it is too late, scientists have been actively developing compounds known as “mechanophores.” These molecular sensors, which can be embedded into the bulk of a polymeric material, serve as an early warning system by chemically reacting to mechanical stress and producing visible light via fluorescence or other phenomena.