This LHP (loop heat pipe) is unprecedented in transporting such a large amount of heat without electricity.

In a groundbreaking development, scientists at Nagoya University in Japan have created the world’s most powerful loop heat pipe (LHP), capable of transporting an astounding 10 kilowatts of heat without using any electricity. This innovation promises to revolutionize energy efficiency across multiple industries, from electric vehicles to data centers.

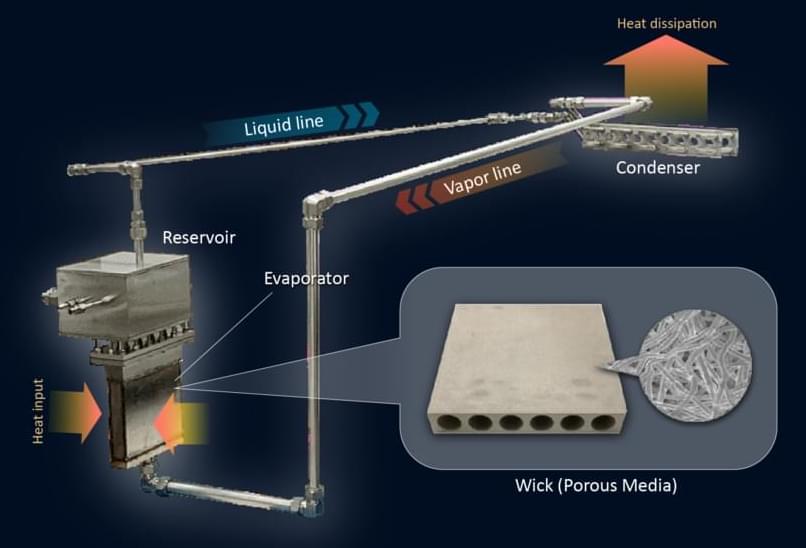

Understanding Loop Heat Pipes

Before delving into the significance of this breakthrough, let’s explore what loop heat pipes are and how they work. LHPs are passive heat transfer devices that use the principles of phase change and capillary action to move heat from one place to another. They consist of an evaporator, a condenser, and connecting pipes filled with a working fluid.