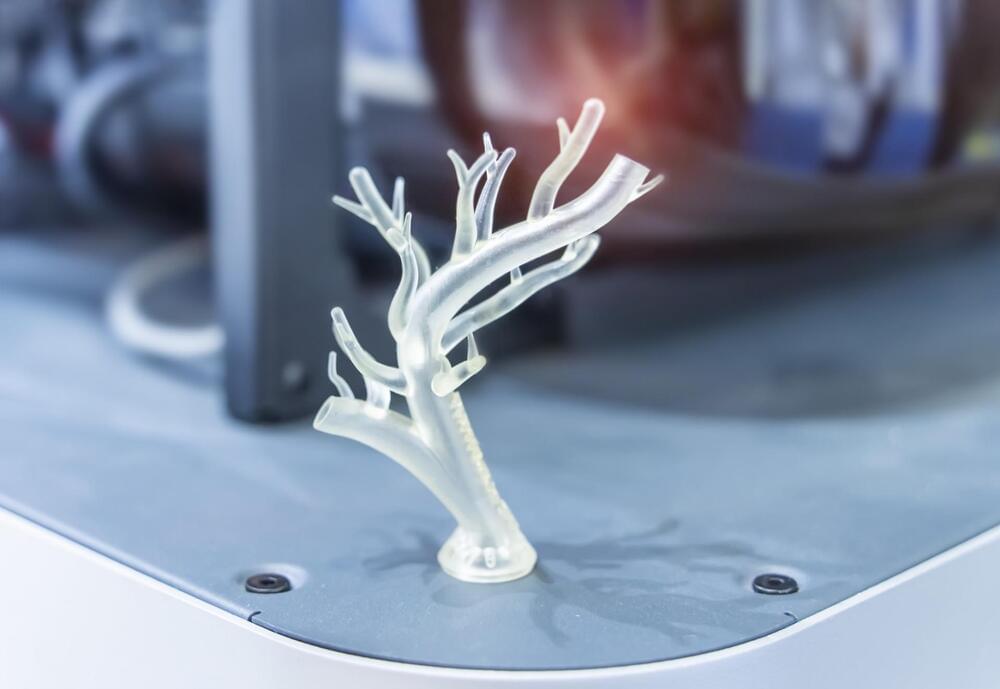

Performance Factors Include Spike Geometry

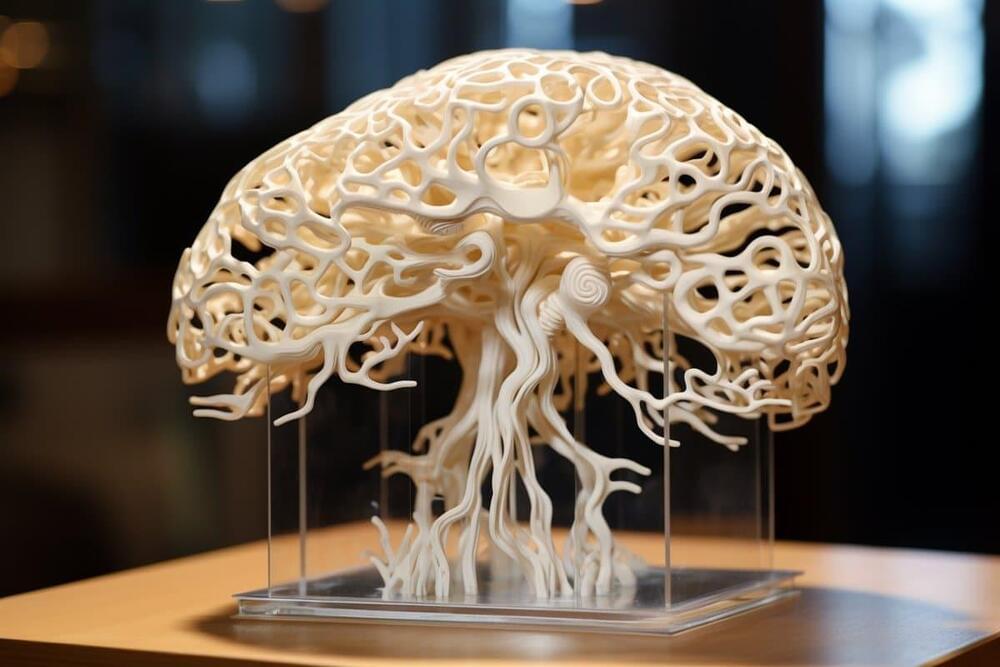

This technology is perfectly suited to the spike plates in bobsleigh, which, until now, was essentially off-the-shelf. 3D printing opens up entirely new possibilities. Performance factors such as geometry – where exactly the spikes placed, the number of struts and teeth, and the weight can be efficiently varied. The spike plates can be printed quickly and inexpensively, tested by athletes until the optimal result is achieved. There is no longer a standard; the efficiency of the process allows for the production of individual plates for each athlete. The ongoing optimisations are expected to be completed by the 2026 Winter Olympics. The experts are also targeting the stiffness of the plates and, consequently, the shoes because not every athlete performs best with the same shoe stiffness.

Another milestone in this journey was reached this year. Various materials for 3D printing are now available for the spikes, tested by athletes. The use of special construction software is also new. It is utilised to optimise components for vehicles as well as equipment for BMW Group production systems in terms of weight and stiffness. This software also aids engineers at the BMW Group in designing the spike plates. It allows for the rapid, automated, and, above all, individually tailored creation of the respective 3D print data. The preferred parameters of each athlete – such as geometry, stiffness, number, and shape of spikes – are automatically incorporated into the design and adapted to the individual plates, based on 3D scans of the athletes’ shoes. This algorithmic design process results in significant time savings and maximum variability.