Entering an invisible doorway to catch a train at King’s Cross station in London is a renowned fictional scene from the Harry Potter series. In recent decades, physicists have been trying to produce a similar effect by focusing their research efforts on illusion devices.

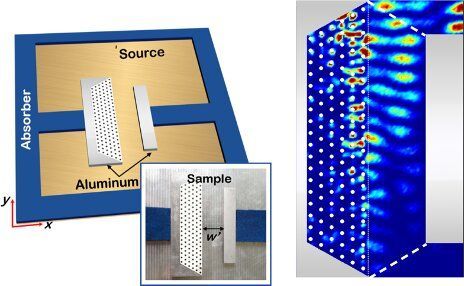

Illusion devices are devices that can change the optical properties of objects to match those of other virtual objects or make them apparently invisible, producing an illusion. Two common types of illusion devices are super-scatterers and invisible gateways. The first are designed to scatter light and the second to bounce back light rays through a physical gateway.

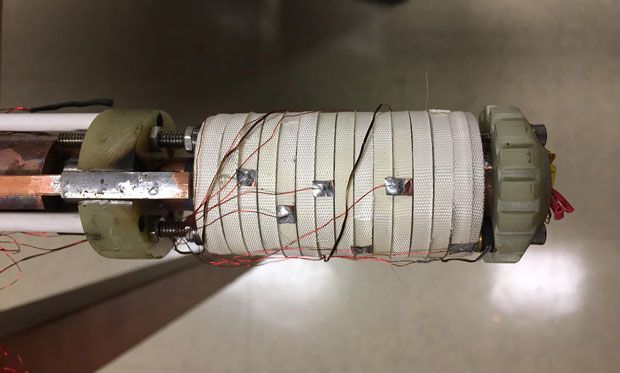

From a theoretical standpoint, super-scatterers and invisible gateways have so far been primarily studied in the context of transformation optics and folded geometry transformations (i.e., the visual, illusory transformation of objects into other objects). Experimentally realizing these devices, however, requires the use of metamaterials with specific properties (e.g., a negative permittivity and permeability) that can be difficult to employ in fabrication processes.