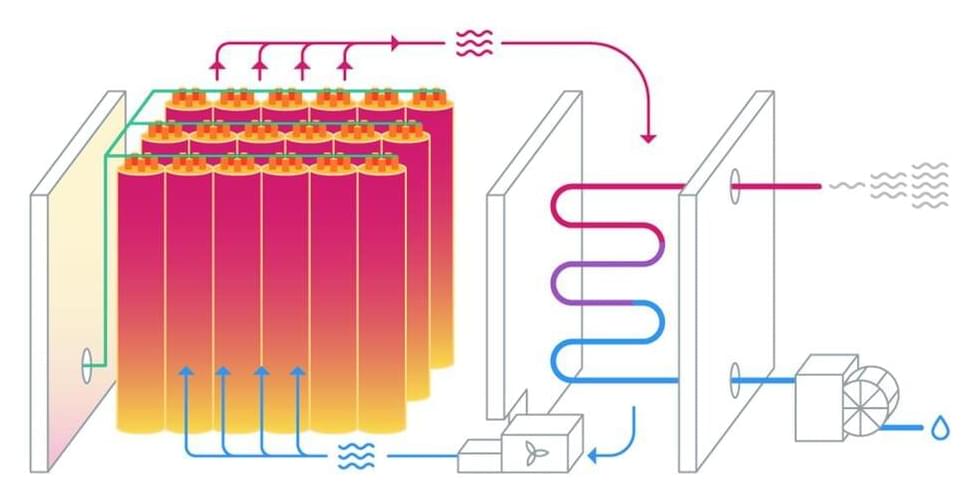

Industrial heat consumes a huge proportion of global energy. Rondo Energy says its brick-toasting heat storage device is so cheap and efficient that it makes decarbonization an instant no-brainer across a huge range of industries. Bill Gates agrees.

According to 130,000 years’ worth of data on what mammals have been eating, we’re in the midst of a mass biodiversity crisis. Not great!

This revelation was borne of a new study, conducted by an international team of researchers and published in the journal Science, that used machine learning to paint a detailed past — and harrowing future — of what happens to food webs when land mammals go extinct. Spoiler alert: it’s pretty grim stuff.

“While about 6 percent of land mammals have gone extinct in that time, we estimate that more than 50 percent of mammal food web links have disappeared,” Evan Fricke, ecologist and lead author of the study, said in a press release. “And the mammals most likely to decline, both in the past and now, are key for mammal food web complexity.”

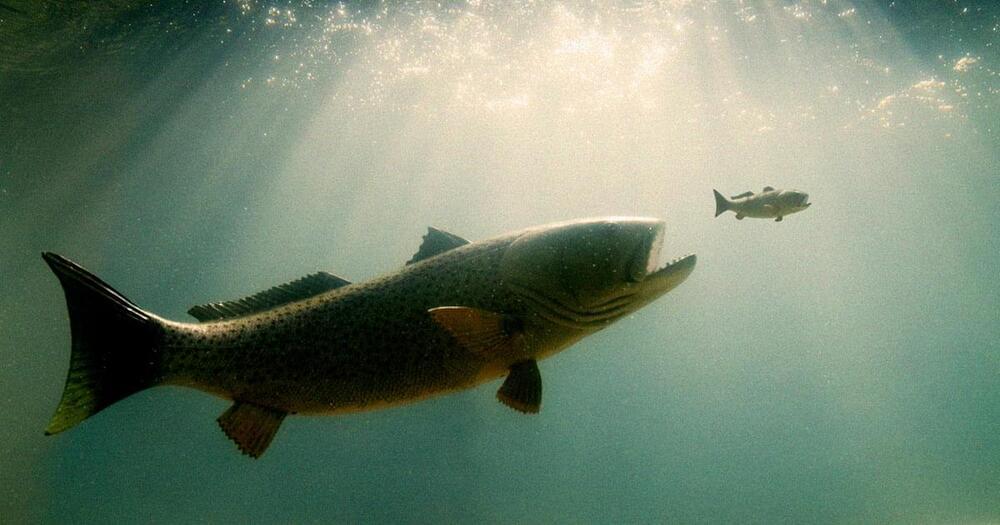

This is also the fastest IPMSM built with commercialized lamination materials.

Researchers at the University of New South Wales Sydney have developed a new electric motor that can clock 100,000 revolutions per minute. The high power density achieved as a result of this new design could help reduce the weight of electric vehicles (EVs) and thereby increase their range, a university press release said.

EV makers around the world have been looking for ways to address the range anxiety of their battery-powered vehicles. One of the options is to increase the size of the battery pack, which also increases the weight of the vehicle, creating more problems to solve.

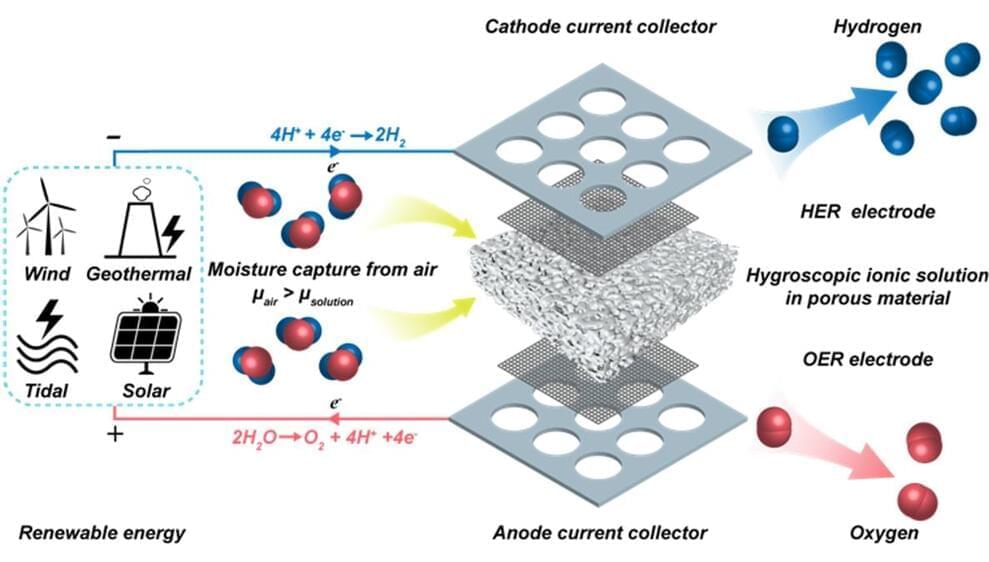

Australian researchers have developed and tested a way to electrolyze hydrogen straight out of the air, anywhere on Earth, without requiring any other fresh water source. The Direct Air Electrolyzer (DAE) absorbs and converts atmospheric moisture – even down to a “bone-dry” 4% humidity.

Such a machine could be particularly relevant to a country like Australia, which has ambitions as a clean energy exporter, along with enormous solar energy potential – but also widespread drought conditions and limited access to clean water. Decoupling hydrogen production from the need for a water supply could allow green hydrogen to be produced more or less anywhere you can ship it out from – and since water scarcity and solar potential often go hand in hand, this could prove a boon for much of Africa, Asia, India and the Middle East, too.

Chemical engineers at Melbourne University came up with what they describe as a simple design: an electrolyzer with two flat plates acting as anode and cathode. Sandwiched between the two plates is a porous material – melamine sponge, for example, or sintered glass foam. This medium is soaked in a hygroscopic ionic solution – a chemical that can absorb moisture from the air spontaneously.

Underwater robots that peered under Antarctica’s Thwaites Glacier, nicknamed the “Doomsday Glacier,” saw that its doom may come sooner than expected with an extreme spike in ice loss. A detailed map of the seafloor surrounding the icy behemoth has revealed that the glacier underwent periods of rapid retreat within the last few centuries, which could be triggered again through melt driven by climate change.

Thwaites Glacier is a massive chunk of ice — around the same size as the state of Florida in the U.S. or the entirety of the United Kingdom — that is slowly melting into the ocean off West Antarctica (opens in new tab). The glacier gets its ominous nickname because of the “spine-chilling” implications of its total liquidation, which could raise global sea levels between 3 and 10 feet (0.9 and 3 meters), researchers said in a statement (opens in new tab). Due to climate change, the enormous frozen mass is retreating twice as fast as it was 30 years ago and is losing around 50 billion tons (45 billion metric tons) of ice annually, according to the International Thwaites Glacier Collaboration (opens in new tab).

The Thwaites Glacier extends well below the ocean’s surface and is held in place by jagged points on the seafloor that slow the glacier’s slide into the water. Sections of seafloor that grab hold of a glacier’s underbelly are known as “grounding points,” and play a key role in how quickly a glacier can retreat.

“We think that each car needs to sound for itself.”

It was roughly six years ago when Audi started designing bold soundtracks for its growing line of hybrids and EVs. Why did the 111-year-old carmaker need custom sounds for its forward-looking product line? It all comes down to one thing: electric vehicles are practically silent, even when traveling at high speeds.

Audi.

The idea of silent cars might seem exciting if you spend your days walking beside noisy urban streets, but quiet cars have a couple of drawbacks. For one thing, they’re dangerous to pedestrians and other drivers. That’s why most countries have a series of regulations that set acceptable ranges for the volume and pitch of the noises that EVs have made. Another down of noiseless EVs is the driving experience. A full-bodied roar makes driving more fun.

University of Portsmouth joins leading AI researchers at DeepMind to help engineer faster acting enzymes for recycling some of the worlds most polluting single use plastics.

The University’s Centre for Enzyme Innovation (CEI) has used DeepMind’s ground-breaking AI system to make strides in their research on circular recycling.