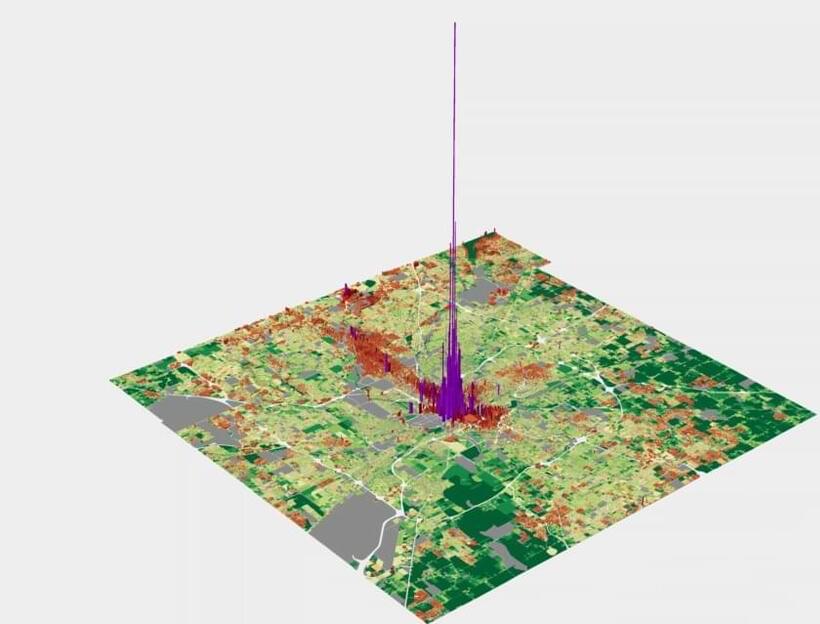

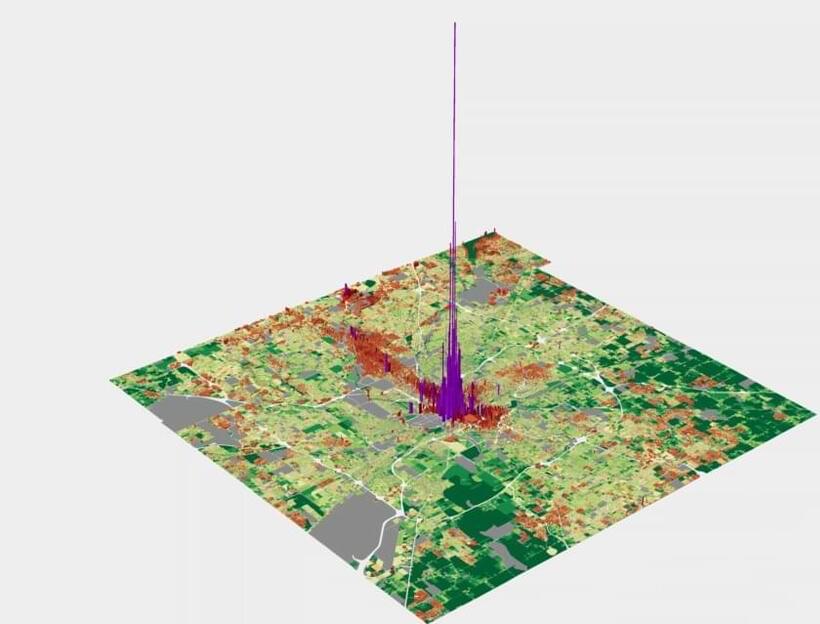

Leadership in Indianapolis has taken strides toward lifting parking minimums, and making their city less car dependent and more transit friendly—all while keeping their fiscal house in order.

TuSimple, a transportation company focusing on driverless tech for trucks, recently transported a load of products with its autonomous truck systems.

The road to fully autonomous trucks is a long and winding one, but it’s not an impossible one, and it seems to be in closer reach than fully self-driving cars.

The company in charge of the feat was TuSimple, a transportation company focusing on driverless tech for trucks. Eighty percent of the journey, or 950 miles (1,528 km), was driven by the autonomous system, with a human at the wheel for the other 20 percent of the cross-country trip, and at-the-ready to take over the wheel if anything faulted with the technology.

Teams of mobile robots could be highly effective in helping humans to complete straining manual tasks, such as manufacturing processes or the transportation of heavy objects. In recent years, some of these robots have already been tested and introduced in real-world settings, attaining very promising results.

Researchers at Northwestern University’s Center for Robotics and Biosystems have recently developed new collaborative mobile robots, dubbed Omnid Mocobots. These robots, introduced in a paper pre-published on arXiv, are designed to cooperate with each other and with humans to safely pick up, handle, and transport delicate and flexible payloads.

“The Center for Robotics and Biosystems has a long history building robots that collaborate physically with humans,” Matthew Elwin, one of the researchers who carried out the study, told TechXplore. “In fact, the term ‘cobots’ was coined here. The inspiration for the current work was manufacturing, warehouse, and construction tasks involving manipulating large, articulated, or flexible objects, where it is helpful to have several robots supporting the object.”

Sandy and Cory discuss the evolution of Model 3 and Model Y bodies in white over the last five years. Sandy points out the massive advancements that have been made and encourages other OEMs to pursue similar efficiency and lean design.

We’d like to thank our partners at Anker for sponsoring this video! Use code “MunroAnker” to get $200 off here: https://click.linksynergy.com/fs-bin/click?id=viLaEb0gUZc&am…mp;subid=0

If you like the content you’re seeing, please consider visiting our website or subscribing to our Patreon group for exclusive content.

PATREON: https://www.patreon.com/MunroLive.

MUNRO LIVE LINKEDIN: https://www.linkedin.com/company/munro-live.

MUNRO MERCH: https://teespring.com/stores/munro-live-store.

Presently available in France, the “Electric As You Go” program is for private customers who wish to change their old vehicle to an affordable, sustainable one. Trying to break through ‘” the cost is too much to invest in an EV” scenario (which becomes more disputable each hour of each day), Stellantis introduced “Electric As You Go” and is promoting a more affordable long-term rental program dedicated to battery electric vehicles (BEVs).

The program claims it is efficiently designed to offer breakthrough competitive prices to Stellantis customers. The offer is starting in France and looks hopeful.

There is the customary but “limited” initial down payment and a monthly fee that starts from €110 per month plus a cost of 7 cents per kilometer with a 500 km minimum per month. This new offer frames itself as a breakthrough project. “The main goal of the program is to offer the opportunity to better adapt the total cost of the vehicle to its real use.”

✅ http://onlydreamersallowed.com.

Motivational Clothing Brand.

✅SELF-HYPNOSIS AUDIO PROGRAMS: http://bit.ly/2RGCade (Reprogram Your Subconscious)

✅6 Hz Auto-Suggestion Program.

https://beinspiredchannel.com/download/thetaaudioprograms/

✅Motivational Alarm Tones.

https://beinspiredchannel.com/alarms.

►Footage licensed through:

Videoblocks.

►Music https://bit.ly/34ZqEAr.

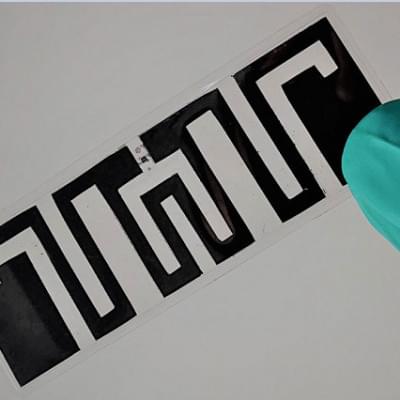

“This is a significant milestone in renewable technology production. From touch screen displays, biosensors, radio frequency identification tags, electric vehicle batteries, and more, the technology’s applications are vast,” said Stuart Jara, HydroGraph chief executive officer.

With growing possibilities for printed electronics every day, the need for conductive inks like graphene ink is on the rise. HydroGraph’s highly competitive cost and mass production method for high quality graphene opens up a wealth of opportunity for the practical applications of conductive ink patterns.

“Once the ink is made, it can then be deployed in regular inkjet printers to make small-scale, flexible electronics. This puts manufacturing capabilities into the reach of many, making it far more accessible,” said Dr. Chris Sorensen, HydroGraph vice president R&D.